This policy aims to prevent accidental release of energy that could result in injury to associates by establishing procedures for locking out and tagging out equipment during maintenance or servicing.

Only authorized associates may apply locks and tags in accordance with this program.

Lockout / Tagout Roles

Authorized Associate: A person who locks out or tags out machines or equipment to perform servicing or maintenance.

Affected Associate: An employee who operates or works near equipment undergoing lockout/tagout.

Other Associate: Any employee or contractor who may be in an area where energy control procedures are used.

Preparation:

Overview

Definitions

Responsibilities

Lockout Tagout Process

Group Lockout

Shift Changes

Contractor Exchange of Procedures

Emergency Lockout Removal

Training Requirements

Audits

Records

This program is designed to protect against the inadvertent or unintended release of energy, movement, or flow in electrical, mechanical, or material systems, which could result in injury to Yaskawa associates.

Lockout of these systems must be utilized, where needed, to safely allow entrance into or close contact with equipment.

These procedures will be used to ensure that machines or equipment being inspected, serviced or maintained are isolated from all potentially hazardous energy and locked out before Yaskawa associates perform any activities where unexpected energizing, start up, or release of stored energy could cause injury.

All Yaskawa associates and contractors will comply with the requirements of this program. Only authorized Yaskawa associates may apply locks and tags and only in accordance with this program.

Affected Associate

An employee whose job required him/her to operate or use a machine or piece of equipment on which servicing or maintenance is being performed under lockout or tagout, or whose job requires him/her to work in an area in which such servicing or maintenance is being performed.

Authorized Associate

A person who locks out or tags out machines or equipment in order to perform servicing or maintenance on that machine or equipment. An affected employee becomes an authorized employee when that employee's duties include performing servicing or maintenance covered by this policy.

NOTE: An associate or contractor may be authorized in one area, such as production, and only affected in other areas, such as laboratories. Authorization is determined by the location and type of equipment being worked on.

Other Associate

An employee or contractor who may be in an area where energy control procedures may be utilized.

Capable of Being Locked Out

An energy-isolating device is considered capable of being locked out if it:

EHS Risk Mitigation Manager

A carefully sequenced procedure should be developed for the lockout of each potentially hazardous machine. This procedure should be in writing. A copy of the procedure, laminated to protect it from damage, should be kept with the machine.

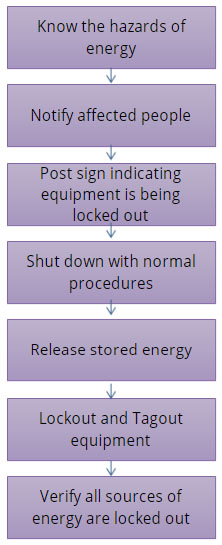

The Authorized Associate should know before beginning lockout procedures the type, magnitude, and hazards of energy that the machine or equipment utilizes.

Notify all Affected Employees when, where, and why a lockout system is going to be utilized.

Post lockout sign in a visible position on the machine or equipment to be lockout.

If the machine or equipment is operating, shut it down by the normal stopping procedure (depress stop button, open toggle switch, etc.).

Operate the switch, valve, unplug, quick disconnect, or other energy isolating devices so that the equipment is isolated from its energy sources. Stored energy such as springs, elevated machine members, rotating flywheels, hydraulic systems, air, gas, steam, or water pressure, etc. must be dissipated or restrained by methods such as reposition, blocking, bleeding, etc.

Lockout the energy isolating devices with the specially assigned red individual locks. Use yellow cylinder boxes to lock out plugs, quick disconnects, or remote switches. Sign, date, and attach Lockout Identification Tag through the lock pin.

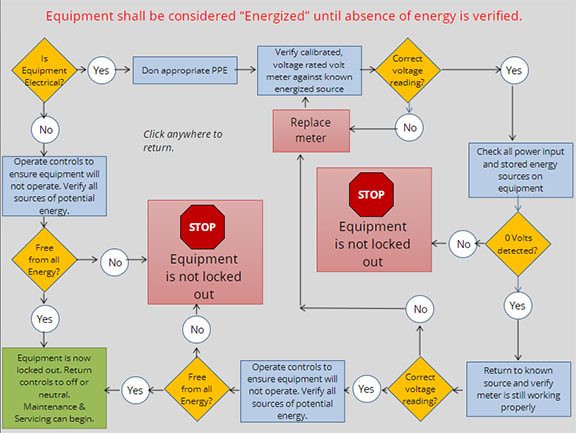

After ensuring that no Employees are exposed, and as a check on having properly disconnected the energy sources:

Inspect the work area to ensure that nonessential tools and material have been removed and to ensure that the machine/equipment components are operationally intact.

Notify and remove Employees from the machine/equipment area.

Remove the lockout devices by the Authorized Employee who applied the device.

Energize and proceed with testing/positioning.

De-energize all systems and reapply energy control measures as outlined in Sequence of Lockout Procedures.

After the servicing and maintenance is completed, and the equipment is ready for normal production operations, check the area around the machines or equipment to ensure that no one is exposed to any danger.

After all tools have been removed from the machine or equipment, guards have been reinstalled and Employees are in the clear, the individual applying the lockout device will remove all lockout devices, identification tags, and signs.

Operate the energy isolating devices to restore energy to the machine or equipment.

If more than one individual is required to lockout equipment, each individual will place their own personal lockout device on the energy isolating devices.

When an energy-isolating device cannot accept multiple locks, a special red multiple lockout hasp will be used.

Multiple-Lock Hasp

A multiple-lock hasp shall be used if work is expected to be transferred between shifts.

The latter authorized associate shall apply her or his lock before the prior associate(s) remove their locks.

Yaskawa and the outside contractor must inform each other of their respective LOTO procedures. Yaskawa associates must comply with the restrictions of the contractor's program is more stringent, and vise versa.

The absent Authorized Employee’s Manager must verify that the Authorized Employee who applied the device is not at the facility.

The Manager must be present at the machine/equipment before another Authorized Employee can use the emergency spare key or lock cutter to remove lockout device.

All reasonable effort must be made to contact authorized Employee to inform them that their lockout device has been removed.

The Authorized Employee’s Manager must notify the Authorized Employee(s) before they resume work at the facility that their lockout device has been removed.

The first time a Yaskawa Associate becomes Authorized as a Yaskawa employee, he/she will complete the training with the instructor physically present. Subsequent training can be completed using e-training with instructor access available through email or phone.

This training shall include, as a minimum, the following:

Affected Associates are workers who are affected by lockout/tagout operations in their work area (e.g. machine operator). This training may be conducted via e-training as long as immediate access to an instructor is available to answer questions. (This may be via phone.)

This training shall include, as a minimum, the following:

Each Yaskawa America, Inc. Associate shall receive “Other Associate Lockout/Tagout” training within:

An annual audit of each energy control procedure must be completed.

This audit shall include a review of each associate’s responsibilities under the energy control procedure being inspected.

Each energy control procedure must be separately inspected at least annually to ensure that the energy control program is being properly utilized.

At a minimum, these inspections must provide for the demonstration of the procedures and must be performed while authorized employees perform servicing and/or maintenance activities on machines or equipment. Specifically, the inspector must be able to determine whether:

| Record Title | Retained by | Disposition |

|---|---|---|

| Authorized Associate Training | Yaskawa Learning Management System | Employment Tenure plus 5 Years |

| Qualified Associate Training | Yaskawa Learning Management System | Employment Tenure plus 5 Years |

| Other Associate Training | Yaskawa Learning Management System | Employment Tenure plus 5 Years |

| Machine/Equipment Specific LOTO Procedure | Kept with Machine/Equipment | Kept with machine until updated or machine is no longer in facility |

| Energy Control Audits | Maintained by Cost Center Manager | Min 5 years |

| Rev # | Description | Release Date | Approved by |

|---|---|---|---|

| 0 | Conversion of old safety documents, rewrite, and issue | 5/17/2016 | Thurwanger |

| 1 | Reformatting, no substantive changes to content | 9/12/2016 | Thurwanger |

| 2 | Added reference to NFPA 70E tables | 12/2/2019 | Thurwanger |

| 3 | Added Contractor Exchange of Procedures section | 2/11/2026 | Thurwanger |

| Review Date | Reviewed by | Changes Required (Yes/No) | Revision # if updated |

|---|---|---|---|

| 2/15/2017 | Thurwanger | No | |

| 1/10/2018 | Thurwanger | No | |

| 1/17/2019 | Thurwanger | Yes | 2 |

| 1/9/2020 | Thurwanger | No | |

| 1/19/2021 | Thurwanger | No | |

| 1/13/2022 | Thurwanger | No | |

| 1/26/2023 | Thurwanger | No | |

| 1/11/2024 | Thurwanger | No | |

| 1/16/2025 | Thurwanger | No | |

| 2/11/2026 | Thurwanger | Yes | 3 |