Introduction

Objectives

Responsibilities

Scope

References

Normal Operation of Electrical Equipment

Equipment / Interlocks / Housekeeping

Flexible Cord Sets

Defective Equipment

Work On/Near Exposed Energized Conductors

Qualified and Unqualified Workers

Host and Contract Employer Responsibilities

Test Instruments and Equipment

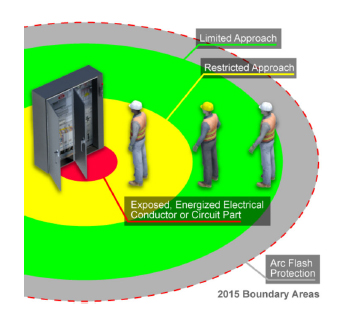

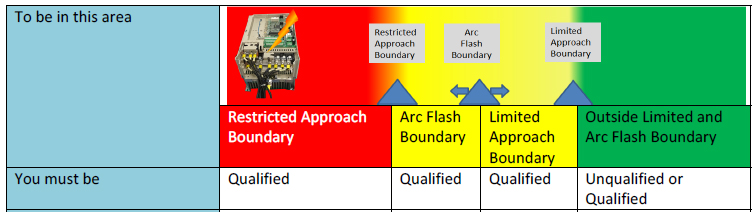

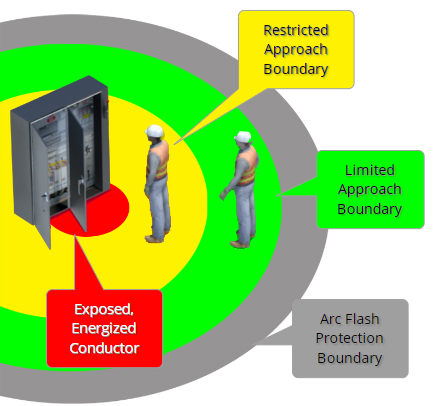

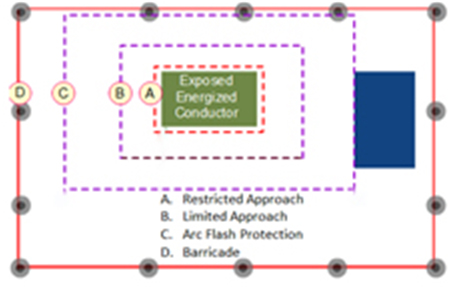

Approach Boundaries

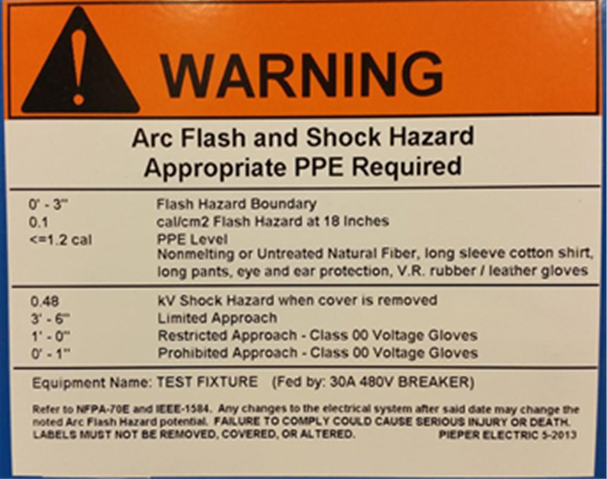

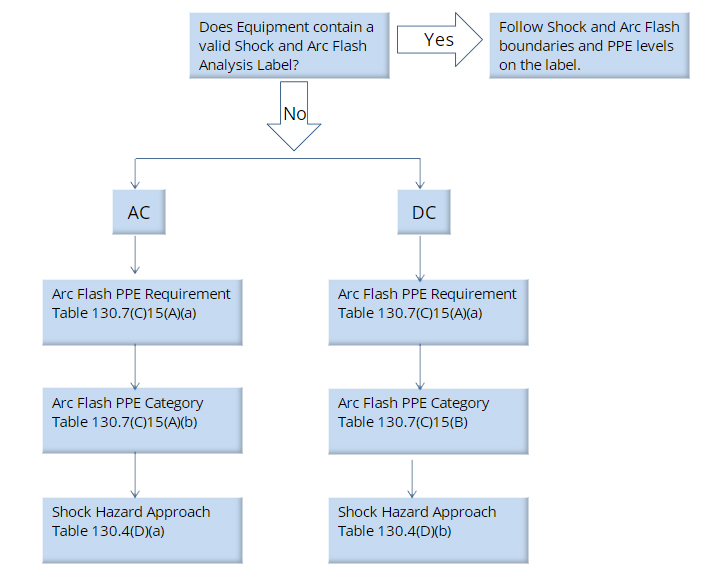

Hazard Analysis

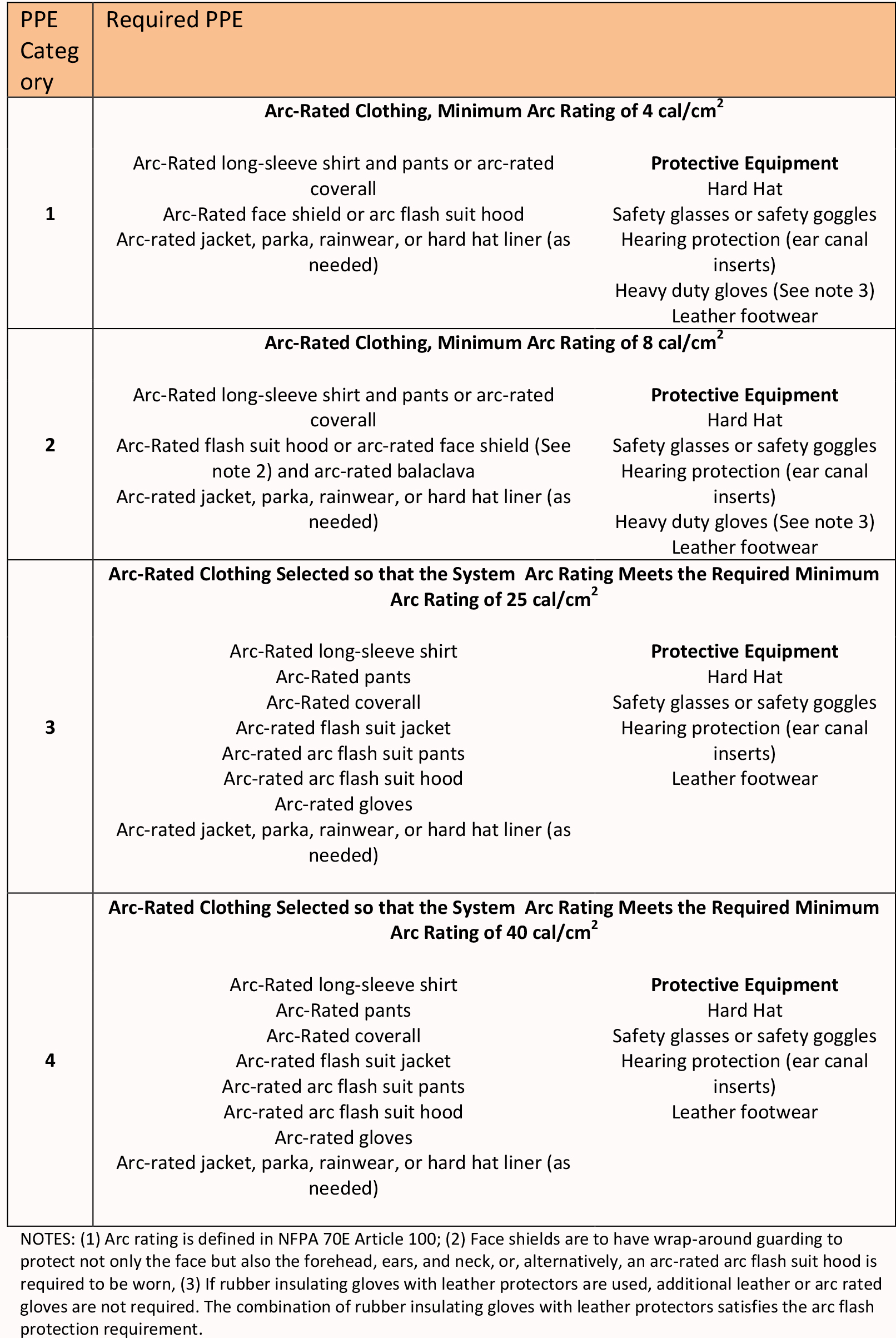

PPE Categories

Other Precautions

Work On or Near Overhead Lines

Electrical Power and Lighting Circuits

To establish a program meeting or exceeding acceptable standards for electrical safety-related work practices. This program includes requirements for the comprehensive training of qualified and unqualified workers relating to:

The primary objective of this policy is avoid injuries related to electrical contacts.

Responsibility of Yaskawa America, Inc.

This policy affects all Yaskawa America, Inc. employees, contractors and visitors.

Title 29 Code of Federal Regulations Parts 1910.331-360 “Electrical Safety-Related Work Practices”

NFPA 70E Standard

Yaskawa America, Inc. Control of Hazardous Energy Policy

| Approach Distances | Must be established whenever work is to be conducted on electrical systems or components that are not in an electrically safe work condition. | |

| Flash Protection Boundary | Distance beyond which appropriate flash protection equipment is required to prevent incurable 2nd degree burns. NOTE: The flash protection boundary can be inside or outside of the limited approach boundary. |

|

| Limited Approach Boundary | Shock protection boundary designed to keep nonqualified persons at a safe distance from exposed electrical components. Only qualified workers are allowed within this boundary. | |

| Restricted Approach Boundary | Secondary shock protection boundary to prevent accidental contact with live parts. Only qualified personnel with proper protective equipment are allowed within this boundary. | |

| Arc Flash Hazard | A dangerous condition associated with the possible release of energy caused by an electric arc.

|

|

| Arc Rating | Expressed in cal/cm², the arc rating indicates the level of arc flash protection. It determines appropriate personal protective equipment. |  |

| Barricade | A physical obstruction to prevent contact with equipment or energized conductors and restrict unauthorized access. | |

| Disconnecting Means | A device to disconnect a circuit from its power source, which must support being locked out for safety. | |

| Electrical Conductor |

|

|

| Exposed Electrical Conductor | Capable of being inadvertently touched or approached closer than a safe distance. Not insulated. | |

| Fixed Equipment | Equipment fastened in place or connected by permanent wiring methods (hard-wired). | |

| Portable Electrical Equipment | Includes cord and plug-connected equipment, such as extension cords. | |

| Qualified Person |

|

|

| Unqualified Person | Not permitted to work near live electrical conductors. | |

| Energized | All electrical equipment is considered energized until confirmed otherwise by qualified personnel through proper procedures. | |

| De-energized | Electrical conductors with no current, confirmed by proper procedures. Considered energized until verified otherwise. |

There are four categories of work:

Using tools and equipment that are properly grounded or double‐insulated and with no damage to insulation. There is no exposure to live electrical conductors.

Work on products, equipment, or facilities on electical conductors in which no electrical current has been verified.

An Energized Work Permit is required when it is necessary to work within the restricted approach boundary of exposed parts at 50V or above except for:

Qualified associates who use appropriate safe work practices may perform work within the restricted approach boundary of exposed energized parts at 50V or above for the following activities:

The risk associated with normal operation of electrical equipment is minimal, given the following conditions:

Refers to equipment fastened in place or connected by permanent wiring methods (hard wired).

Installation

Only Yaskawa approved electrical contractors shall install fixed equipment.

Yaskawa approved contractors are required to ensure the equipment is properly installed and wired in accordance with applicable industry codes and standards including the manufacturer’s instructions.

Maintenance

Maintenance of fixed equipment shall be completed per manufacturers recommendation by competent personnel.

If Lock-Out/Tag-Out is required to perform the maintenance, Lock-Out/Tag-Out shall be completed by a qualified associate following the requirements detailed in Yaskawa’s Lock-Out/Tag-Out Policy.

Before beginning work on deenergized circuits or equipment, a qualified person must verify that the equipment cannot be restarted. Before reenergizing the circuits or equipment, the qualified person must conduct tests and visual inspections to ensure that it can be done safely.

Consumer Products

Each associate is responsible for ensuring the electrical consumer products she/he uses is free from exposure to energized circuits or parts.

Portable ladders must have nonconductive side-rails if there is potential for contact with energized parts.

Interlocks may only be defeated by a qualified person and only while she/he is working on the equipment.

The interlock system must be made operable when the work is complete.

Housekeeping duties must be performed at sufficient distances to avoid contact with live parts.

Housekeeping shall not be performed within the limited approach distance or the arc flash boundary, whichever is farther from the exposed live conductors.

Electrically-conductive cleaning materials may not be used within the limited approach distance or the arc flash boundary, whichever is farther from the exposed live conductors.

NOTE: For the purpose of this procedure, there is no distinction between a product or equipment with a known defect and a product or equipment that is suspected to have a defect. Suspect products and equipment are considered defective.

Defective equipment shall be removed from use as soon as the defect, or suspected defect, is identified. Under no circumstance shall a Yaskawa associate attempt to use defective or suspected defective material.

An “Out of Service” or “Do Not Use” tag shall be placed on the equipment and the appropriate personnel notified. If an associate does not know who the appropriate personnel is, he/she shall notify his/her supervisor.

Repair of defective equipment shall only be performed by competent authorities following manufacturer’s instructions.

Products/equipment that cannot be repaired shall be destroyed in a manner that later repairs cannot be attempted by other people.

Before working on parts which have been deenergized, the circuits which energize the parts must be properly locked-out and tagged-out per Yaskawa America, Inc.’s Lock-Out/Tag-Out Policy.

Parts of electric equipment and circuits that have been deenergized, but have not been locked out and tagged, are to be treated as energized.

Before beginning work on deenergized circuits or equipment, a qualified person most verify that the equipment cannot be restarted. Before

reenergizing:

This section addresses the requirements while testing, voltage measurement and troubleshooting. No Yaskawa associate shall perform Permit Required Work.

Working on or near exposed energized parts is necessary to test manufactured products to ensure the safety of Yaskawa customers and ensure the integrity and reliability of Yaskawa products.

Qualified testers must complete all of the training requirements identified in Qualified Associates section and training specific to the products and test equipment with which they will work.

Production testers qualification is facility and product type specific.

After a product has been repaired, either within Yaskawa’s in-house repair facilities or at a customer site, it must be tested to ensure the safety of Yaskawa customers and ensure the integrity and reliability of the product. This test may require working on or near exposed energized parts.

Qualified associates performing repair and field service work must complete all of the training requirements identified in Qualified Associates section.

Associates qualified for repair and field service are qualified by voltage ratings (e.g.: Low Voltage 0-1000V, Medium Voltage 1000V-35,000V, High Voltage >35,000V). Associates qualified to perform medium voltage testing are also qualified to perform low voltage testing.

Yaskawa laboratory workers test product to ensure products meet design, regulatory and statutory requirements. The testing may require working on or near exposed energized parts.

Qualified associates working in the laboratories must complete all of the training requirements identified in Qualified Associates section

Associates qualified for laboratory work are qualified by voltage ratings (e.g.: Low Voltage 0-1000V, Medium Voltage 1000V-35,000V, High Voltage >35,000V).

As an extension of the testing process, troubleshooting may be necessary to diagnose problems found during test. This troubleshooting may require work on or near exposed energized parts.

The qualifications for troubleshooting tested products are the same as the qualification for the test purpose.

It may be necessary to work on or near exposed energized parts to diagnose faults with customer property, either returned to Yaskawa repair facilities or at the customer site.

Associates who are qualified for testing, repair and field service, and laboratory work are also qualified to perform troubleshooting pursuant to their testing qualification.

Qualified facilities associates may have to troubleshoot electrical equipment or services. This troubleshooting may require work on or near exposed energized parts.

Qualified facilities associates must complete all of the training requirements.

Associates who are qualified for facilities maintenance and repair are qualified by voltage ratings (e.g.: Low Voltage 0-1000V, Medium Voltage 1000V-35,000V, High Voltage >35,000V).

Pursuant to Yaskawa’s Lock-Out/Tag-Out (LOTO) procedure, LOTO may require work on or near exposed energized parts. Electrical lock-out procedures require the assumption that electrical parts and services are energized until voltage measurement confirms a lack of electrical energy.

Associates who are qualified to perform product testing and/or troubleshooting are qualified to perform voltage measurement in relation to their qualification.

LOTO qualified associates are qualified to perform voltage measurement.

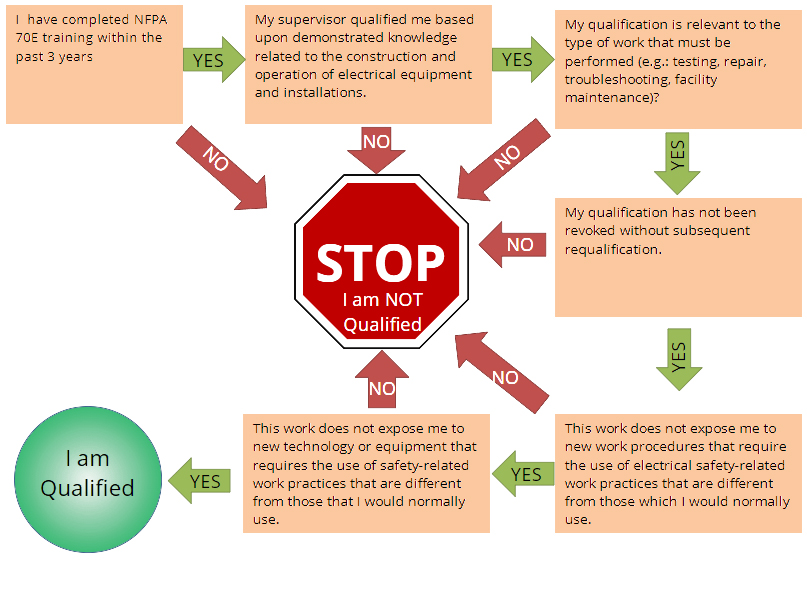

A qualified worker is one who has demonstrated knowledge related to the construction and operation of electrical equipment and installations and has received safety training to identify and avoid the hazards involved.

Qualification is based upon the type of work being performed.

Qualification must be renewed when:

The training required by this section shall be classroom and on-the-job (to demonstrate knowledge and understanding). The type and extent of the training provided shall be determined by the risk to the associate.

The training shall be verified at least annually to ensure the associate training required by this policy and NFPA 70E is current.

The training required in this section shall be documented in the qualified associate’s competency record.

The training and demonstrated understanding shall include:

A Yaskawa associate who has not met all of the criteria to be “Qualified” for the work requiring working on or near exposed energized parts is deemed “Unqualified.”

Unqualified persons shall not work on or near exposed energized parts.

Unqualified associates shall be trained in, and be familiar with, any electrical safety-related practices necessary for their safety. Unqualified associates within production, repair and laboratory areas shall be trained in:

Yaskawa shall inform contract workers of the following:

The contract employer shall ensure that each of its employees who will work within the Yaskawa facility is instructed in the hazards communicated to the contract employer by Yaskawa. This instruction shall be in addition to the basic training provided by the contractor.

The contract employer shall ensure that each of its employees follows the work practices required by this policy and safety-related work rules required by Yaskawa.

The contract employer shall advise Yaskawa of the following:

Only qualified persons shall perform tasks such as testing, troubleshooting and voltage measuring within the limited approach boundary of energized electrical conductors or circuit parts operating at 50 volts or more or where an electrical hazard exists.

Test instruments, equipment and their accessories shall be rated for circuits and equipment where they are utilized.

Test instruments, equipment, and their accessories shall be selected for the environment to which they will be exposed and for the manner in which they will be utilized.

Test instruments and equipment and all associated test leads, cables, power cords, probes, and connectors shall be visually inspected for external defects and damage before each use.

When test instruments are used for testing the absence of voltage on conductors or circuit parts operating at 50 volts or more, the operation of the test equipment shall be verified on a known voltage source before and after an absence of voltage test is performed.

| 1. |  |

While wearing appropriate PPE, check that the voltmeter is working properly by checking it to a known source. |

| 2. |  |

While wearing appropriate PPE, check for voltage on the locked out equipment. Check all potential sources. |

| 3. |  |

While wearing appropriate PPE, check that the voltmeter is still working properly by checking it to a known source. |

Only qualified workers are permitted within any of the approach boundaries (restricted approach, limited approach and arc flash protection boundaries)

Barricades or barriers shall be erected to prevent unqualified workers from entering past the outer boundary.

If barricades or barriers cannot be installed, such as field service, an attendant shall be placed outside of the outer boundary to warn unqualified people to stay outside the boundary areas. The attendant shall remain in the area as long as there is a potential for associates to be exposed to the electrical hazard.

EXAMPLES

|

Production test area in OC/Franklin uses ribbon barrier outside of the outer boundaries. |

|

Production test in BG uses barrier to shield the worker from the exposed conductors. |

|

Labs provide a barrier by using a secured access door. |

Electrical shock and arc flash assessments shall be performed:

A label shall be affixed to the electrical equipment. This label shall include:

When the arc rating is below 1.2 cal/cm2, the following PPE is required:

Personal protective equipment shall be provided (as necessary) by Yaskawa and shall conform to the following standards:

| Items | Standard Number and Title | |

|---|---|---|

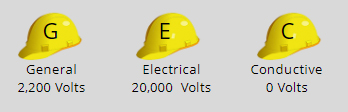

| Head Protection | ANSI Z89.1 Requirements for Protective Headwear for Industrial Workers |  |

| Eye and Face Protection | ANSI Z87.1 Practice for Occupational and Educational Eye and Face Protection | |

| Insulating Gloves | ASTM D 120-02 Standard Specification for Rubber Insulating Gloves | |

| Sleeves | ASTM D 051-02 Standard Specification for Rubber Insulating Sleeves | |

| Leather Protectors | ASTM F 696-02 Standard Specifications for Leather Protectors for Rubber Insulating Gloves and Mittens | |

| Footwear | ASTM F 1117 Standard Specifications for Dielectric Overshoe Footwear ASTM F2412 and ASTM F2413 Standards for Personal Protection Protective Footwear |

Associates shall notify their supervisor if they believe their alertness is impaired due to illness, fatigue or other reasons.

Associates shall not be permitted to work within the limited approach boundary of energized electrical conductors or circuit parts or where other electrical hazards exist while their alertness is recognizably impaired due to illness, fatigue, or other reasons.

Associates shall be instructed to be alert for changes in the job or task that may lead to the associate outside of the electrically safe work condition or expose the associate to additional hazards that were not part of the original plan.

Associates shall be instructed not to reach blindly into areas that might contain exposed energized electrical conductors or circuit parts where an electrical hazard exists.

Associates shall not enter spaces where electrical hazards exist unless illumination is provided that enables the associates to perform the work safely.

Where lack of illumination or an obstruction precludes observation of the work to be performed, associates shall not perform any task within the limited approach boundary of energized electrical conductors or circuit parts operating at 50 volts of more or where an electrical hazard exists.

Conductive articles of jewelry and clothing (such as watchbands, bracelets, rings, key chains, necklaces, metalized aprons, cloth with conductive thread, metal headgear, or metal frame glasses) shall not be worn within the restricted approach boundary or where they present an electrical contact hazard with exposed energized parts.

If work is performed near overhead lines, including buss duct, the lines must be de-energized and grounded, or other protective measures provided before work is started.

Where lines are unguarded and energized, minimum approach distances must be maintained.

No person or equipment shall be work within 10 feet of energized overhead powerlines.

Load rated circuit breakers shall be used for opening and closing circuits. Fuses, terminal lugs and cable splice connections shall not be used to make or break load.

After a circuit has been de-energized by a circuit protective device, the circuit shall not be reenergized until it has been determined safe to do so by a qualified associate.

Only qualified workers may perform testing work on electrical circuits.

Yaskawa Field Service associates shall follow the more restrictive policies of this Yaskawa Safety Manual and the customer’s safety policies.

Yaskawa America, Inc. does not require an Energized Work Permit for troubleshooting and voltage measurement. However, Yaskawa field service associates may encounter a customer who does require an Energized Work Permit for troubleshooting and/or voltage measurement. In these instances the customer’s Energized Work Permit form shall be used.

The customer shall take the lead on the project and is responsible for:

SAF-P-3000 Safety Policy MV Drive Test Area

SAF-F-3001 MV Test Area Power-On/Power Off Checklist

MV Test Facility Trianing

PV Electrical Safety Program

| Record | Maintained by | Retention Time |

|---|---|---|

| Training: Electrical Safety-Related Work Practices | Associate Competency Record Maintained by Supervisor |

Life of Employment |

| Training: NFPA 70E | Associate Competency Record Maintained by Supervisor |

Life of Employment |

| Electrical Shock and Arc Flash Analysis | Equipment Cost Center Manager | 5 years (minimum) |

| Training Title | Audience | Delivery Method | Verification Method | Refresher | Records |

|---|---|---|---|---|---|

| General: Electrical Safety-Related Work Practices | All associates | Electronic or Classroom | Quiz | Change in Procedure | Learning Management System |

| Unqualified Worker: Safety-Related Work Practices and NFPA 70E Awareness | Unqualified workers near areas where Qualified associates work | Electronic or Classroom | Quiz & Supervisor Evaluation | Min. every 3 years, Change in Process or requirements, Observation on unsafe work |

Learning Management System |

| Qualified Workers: Safety-Related Work Practices and NFPA 70E Awareness | Qualified Associates | Electronic or Classroom | Quiz & Supervisor Evaluation | Min. every 3 years, Change in Process or requirements, Observation on unsafe work |

Learning Management System |

| Qualified Workers: NFPA 70E | Qualified Associates | Classroom | Supervisor Evaluation | Min. every 3 years, Change in Process or requirements, Observation |

Learning Management System |

Breaching this policy may result in an injury. Breaches of this policy may result in disciplinary action being initiated in accordance with Yaskawa America's discipline policy.

| Rev # | Description | Release Date | Approved by |

|---|---|---|---|

| 1 | Conversion of old safety documents, rewrite, and issue | 4/11/2016 | Thurwanger |

| 2 | Updated NFPA 70E Tables | 8/12/2019 | Thurwanger |

| 3 | Added Work on or Near Overhead Lines (Including Buss Duct) | 6/8/2023 | Thurwanger |

| Review Date | Reviewed by | Changes Required (Yes/No) | Revision # if updated |

|---|---|---|---|

| 2/15/2017 | Thurwanger | No | |

| 1/10/2018 | Thurwanger | No | |

| 1/17/2019 | Thurwanger | Yes | 2 |

| 1/9/2020 | Thurwanger | No | |

| 1/19/2021 | Thurwanger | No | |

| 1/13/2022 | Thurwanger | No | |

| 1/26/2023 | Thurwanger | Yes | 3 |

| 1/11/2024 | Thurwanger | No | |

| 1/16/2025 | Thurwanger | No | |

Policy Video