Policy Key Points

Program Availability and Review

This policy is Yaskawa America, Inc.’s written program and will be maintained in accordance with 29 CFR 1910.1200 and updated as required. Where no update is required this document shall be reviewed annually.

Effective implementation of this program requires support from all levels of management within this company. This program shall be communicated to all personnel that are affected by it. It encompasses the total workplace, regardless of number of workers employed or the number of work shifts. It is designed to establish clear goals, and objectives.

This written hazard communication program is available to all employees, during each work shift.

Annually review and revise this written hazard communication program based on company operational requirements or, as required by the OSHA Hazard Communication Standard.

Provide a program for proper labeling of containers, describe other needed forms of warning, and detail the use and purpose safety data sheets (SDS).

Describe how employee information and training requirements will be met, to include the following:

Yaskawa America, Inc. provides employees with information and training on hazardous chemicals in their work area at the time of their initial assignment, periodic refresher, and whenever a new chemical is introduced into their work area that could present a potential hazard.

Information

All associates shall be informed of:

Employee hazard communication training shall be conducted prior to the employee being exposed to chemical hazards.

During new associate orientation, new employees will receive training on the contents of this program and specific training on the chemical hazards that the individuals will be directly working with.

General hazard communication training is provided through an e-learning module accessible through Yaskawa’s learning management system. The e-learning module provides instruction for asking questions directly to an approved HAZCOM instructor.

Work area specific training shall be conducted by the new employee’s direct supervisor.

Additional training will be provided for employees whenever:

Safety Data Sheets are maintained for every substance on the list of hazardous chemicals. These SDS’s are located on the 3E Online system available at this site.

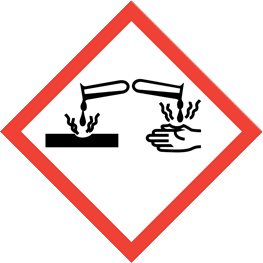

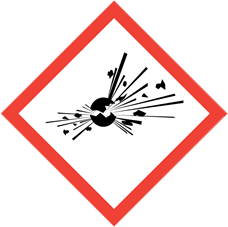

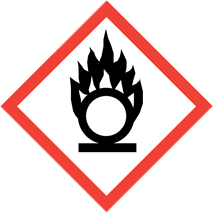

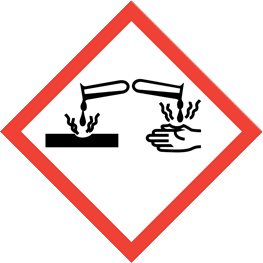

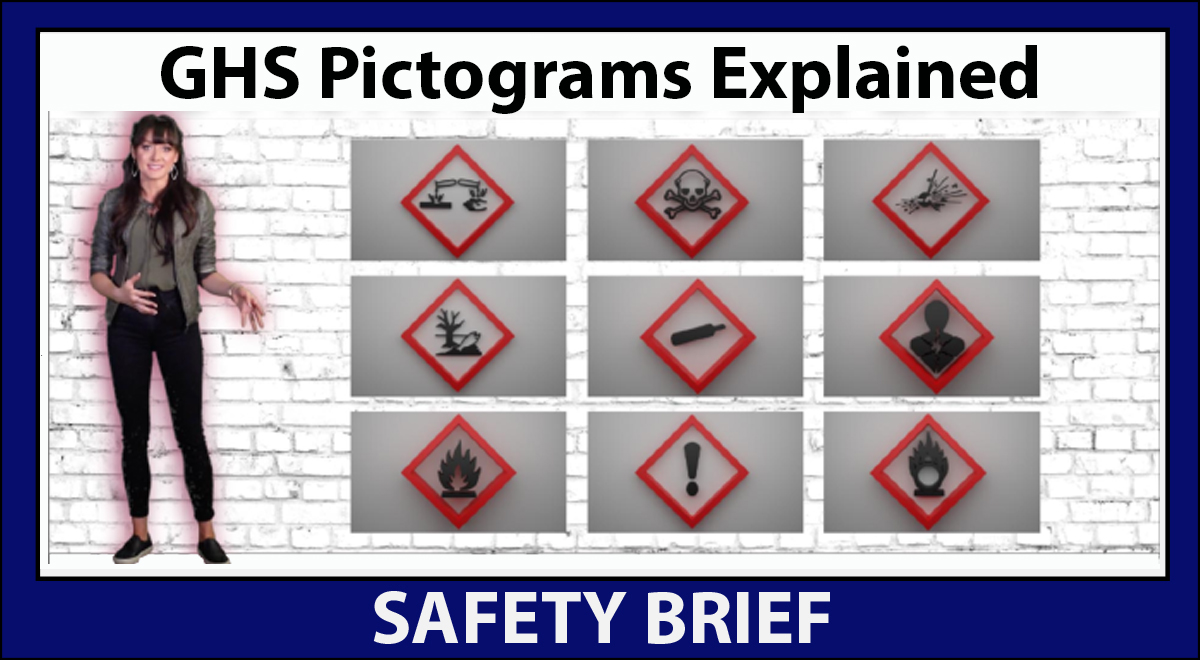

Chemicals are classified using a Globally Harmonized System (GHS) that provides standard language for:

The Safety Brief below provides more detail about the meaning of each of these pictograms.

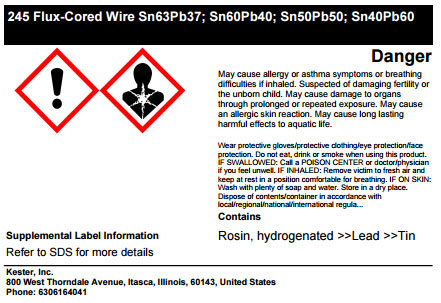

All containers of hazardous chemicals will be properly labeled.

All labels will remain legible and include the identity of the hazardous chemical and the appropriate hazard warning.

Chemicals purchased after December 1, 2015 should have been labeled with the Globally Harmonized System (GHS). Chemicals purchased prior to December 1, 2015 do not require relabeling unless the label becomes illegible.

Secondary container labels printed after December 1, 2016 shall be in the GHS format.

If a chemical label becomes illegible, DO NOT USE the chemical. Immediately notify EHS at EHS@Yaskawa.com or 414-856-2452.

Alternate labeling provisions, such as tags or markings, may be made for containers that are of unusual shape or size and do not easily accommodate a legible label.

Yaskawa associates working at non-Yaskawa facilities shall identify potential hazards using the host company’s list of hazardous chemicals and associated SDS’s.

If the customer does not have a hazardous chemical list, nor SDS’s, the field associate should contact Yaskawa EHS by calling 414-856-2452. EHS will locate an SDS and email it to the Yaskawa associate.

The Yaskawa associate in the field shall ensure that appropriate protective measures, including personal protective equipment, are available and utilized.

If appropriate PPE is not available, the job shall be rescheduled to a time when appropriate PPE is available.

Each contractor bringing chemicals on-site must send the appropriate hazard information, including SDS’s, to EHS@Yaskawa.com prior to brining the chemical into a facility.

All containers of hazardous chemicals brought on-site by an outside contractor must be appropriately labeled in the GHS format.

Outside contractors and contract employees will be advised of any chemical hazards that may be encountered in the normal course of their work in the Yaskawa facility.

Outside contractors and contract employees will be notified of the location of HAZCOM kiosks and have an opportunity to complete instruction on using the 3E Online SDS system.

Hazardous Chemical list and Safety Data Sheets are located on an electronic system located at www.YaskawaSafety.com.

User Name: Yaskawa

Password: Yaskawa

General HAZCOM training records are located in Yaskawa’s learning management system (LMS)

Chemical exposure records are maintained by Human Resources for the employment life of the exposed associate plus 30 years.

General HAZCOM training is required for all new associates and whenever a change to this policy/written program occurs.

Work area specific hazard training is provided by the associate’s immediate supervisor prior to the associate becoming exposed to the hazard.

| Rev # | Description | Release Date | Approved by |

|---|---|---|---|

| 0 | Initial release of electronic policy | 6/10/2016 | Thurwanger |

| 1 | Updated link to Safety Data Sheets | 2/12/2018 | Thurwanger |

| 2 | Added method for anomyous reporting method | 5/11/2019 | Thurwanger |

| 3 | Added Hazardous Chemicals Encounterd while in the field in Field Service section | 3/23/2022 | Thurwanger |

| 4 | Added link to SDS safety brief | 8/6/2024 | Thurwanger |

| Review Date | Reviewed by | Changes Required (Yes/No) | Revision # if updated |

|---|---|---|---|

| 2/15/2017 | Thurwanger | No | |

| 1/10/2018 | Thurwanger | Yes | 1 |

| 1/17/2019 | Thurwanger | Yes | 2 |

| 1/9/2020 | Thurwanger | No | |

| 1/19/2021 | Thurwanger | No | |

| 1/13/2022 | Thurwanger | Yes | 3 |

| 1/26/2023 | Thurwanger | No | |

| 1/11/2024 | Thurwanger | No | |

| 1/16/2025 | Thurwanger | No | |

Policy Video