Policy Key Points

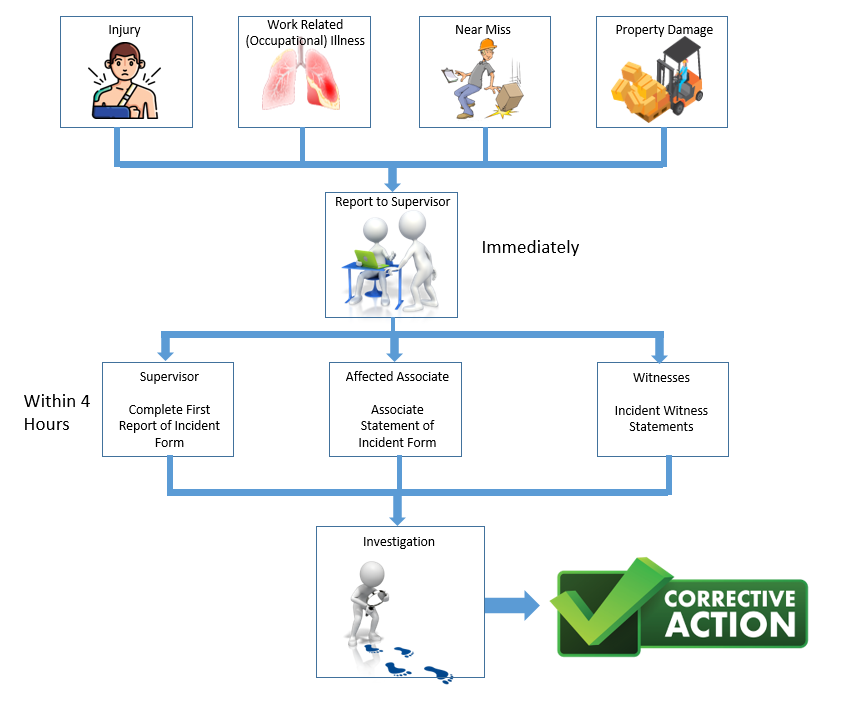

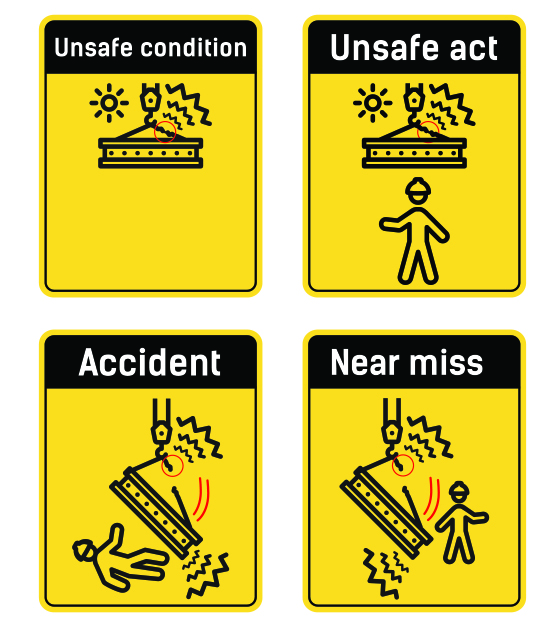

Types of Incidents that Require a First Report of Incident Form

Yaskawa America, Inc. is committed to supporting the recovery and well-being of associates who experience work-related injuries or illnesses. As part of our Incident Reporting and Injury Management process, the Light Duty Program is designed to facilitate the timely and safe return of injured employees to the workplace.

Light duty assignments will be provided to associates with temporary work restrictions, unless doing so would pose a safety hazard to the associate or others. These assignments may involve modifying existing duties or temporarily reassigning the associate to tasks that align with their current capabilities as defined by a medical professional. Denying light duty must be approved by the VP of Human Resources, the VP of Operations, or the Director of Human Resources.

Yaskawa America require all departments to make reasonable efforts to accommodate light duty whenever medically appropriate and safe. The EHS and HR teams will work closely with supervisors and healthcare providers to ensure appropriate placement and oversight of light duty assignments.

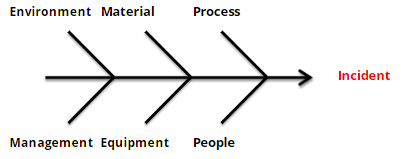

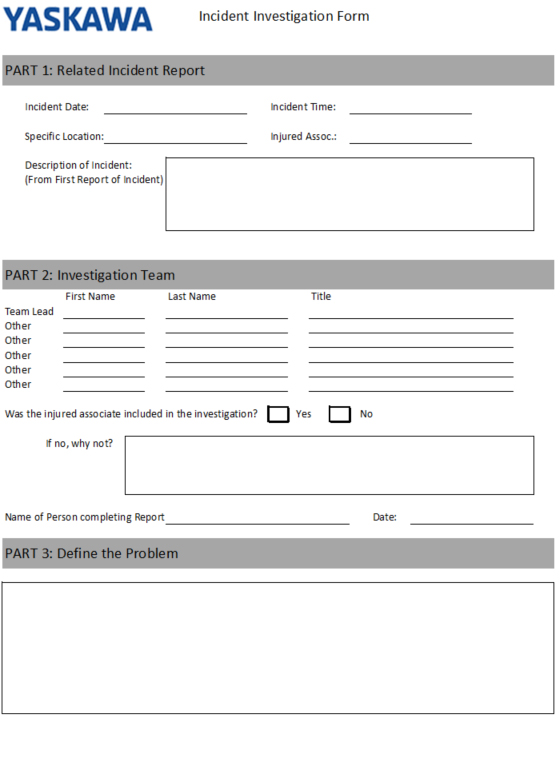

Each incident that requires a First Report of Incident form must also be investigated. The scale and scope of the investigation shall be appropriate to the consequences and potential consequences of the incident.

Investigations shall include examining factors related to the process, the people, material, equipment, environment and management.

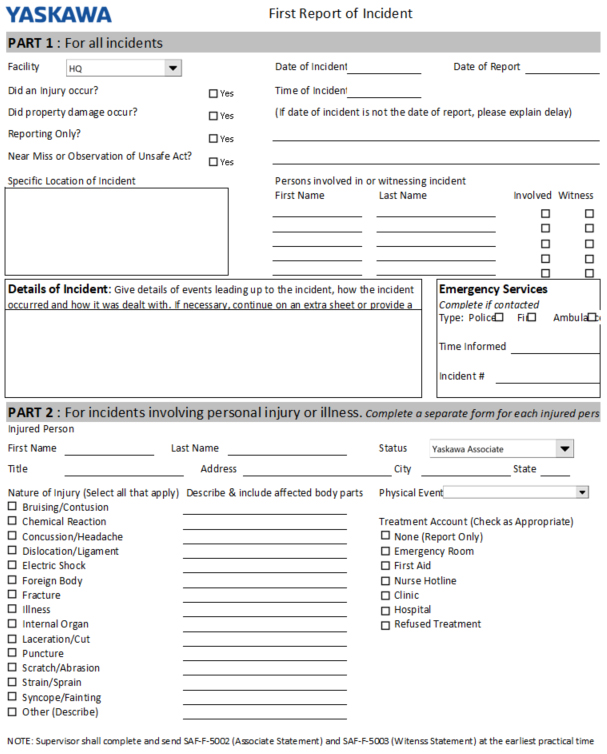

The affected associate's immediate supervisor is responsible for completing the First Report of Incident. When the affected associate's immediate supervisor is not available, the First Report of Incident shall be completed by another member of management.

When the form is submitted, a link to the form is sent to Human Resources, EHS, and the affected associate's immediate supervisor.

After reviewing the First Report of Incident form, and possibly the preliminary investigation report submitted by the area supervisor, the EHS Department or other member of management, may determine that more thorough corrective action is appropriate.

Formal corrective action is required for all incidents, including near misses, that had the potential to result in a Serious Injury or Fatality (SIF).

Incident Corrective Action is a more thorough investigation that involves using an 8-D (eight disciplines) approach. The 8 disciplines are:

Yaskawa America, Inc. encourages the reporting of all safety concerns and incidents. Any form of retaliation against an associate for reporting an injury, illness, or unsafe condition is strictly prohibited.

| Record | Retained by | Retention Time |

|---|---|---|

| First Report of Incident and related documents involving an injury or occupational illness | Human Resources | Tenure of employment plus 5-years (30-years for cases involving occupational exposure to hazardous materials) |

| First Report of Incident and related documents involving property damage | Facilities | Maintained a minimum of 5-years or equipment life (whichever is longer) |

| First Report of Incident and related documents involving a near miss | EHS Department | 5-years (min) |

| Corrective Action Reports | EHS Department | 5-years (min) |

| Rev # | Description | Release Date | Approved by |

|---|---|---|---|

| 0 | Conversion of old safety documents, rewrite, and issue | 4/12/2016 | Thurwanger |

| 1 | Updated form numbers for Associate and Witness statements | 8/24/2017 | Thurwanger |

| 2 | Updated email link to workcomp@yaskawa.com | 2/19/2024 | Thurwanger |

| 3 | Added "Associates Rights" Section | 2/9/2026 | Thurwanger |

| Review Date | Reviewed by | Changes Required (Yes/No) | Revision # if updated |

|---|---|---|---|

| 2/21/2017 | Thurwanger | No | |

| 1/16/2018 | Thurwanger | No | |

| 1/22/2019 | Thurwanger | No | |

| 1/14/2020 | Thurwanger | No | |

| 1/21/2021 | Thurwanger | No | |

| 1/18/2022 | Thurwanger | No | |

| 1/31/2023 | Thurwanger | No | |

| 1/16/2024 | Thurwanger | Yes | 2 |

| 1/21/2025 | Thurwanger | No | |

| 2/9/2026 | Thurwanger | Yes | 3 |

Policy Video

Steps to Complete First Report of Incident Form

1. Collect Statements

2. Analyze the Scene

3. Define the Problem