Policy Key Points

Policy

Introduction

Purpose of this Policy

- To ensure contractors perform work on our sites without posing a threat to their safety,

the safety of our employees and guests, and the environment.

- To ensure contractors are selected based on their demonstrated ability to work safely, follow safety rules and perform their work in an environmentally conscious manner.

- To ensure contractors receive the appropriate Yaskawa specific safety training.

Attachments

Contractor Approval Checklist

Contractor Job Hazard Assessment Form

Contractor Job Hazard Assessment (Sample)

Contractor Declaration of Hazardous Chemicals and SDS Submittal Form

Contractor Policy Waiver Form

Contractor Safety Training

Scope of this Policy

This policy applies to Yaskawa America, Inc. and its subsidiaries,

This policy applies to the following specific service providers:

| Construction |

Service |

|

|

EXAMPLES:

Electricians

Plumbers

Riggers

Cubicle Installation |

EXAMPLES:

Custodial Service

Food Service |

The requirements defined in this policy applies to contractors and subcontractors.

Temporary labor contractors are excluded from the scope of this policy. See SAF‐P‐4002, Yaskawa Temporary Labor Safety Policy.

Contracted training, consulting, software development and engineering companies are excluded from the scope of this policy. See SAF‐P‐4003, Contracted Training, Engineering, and Consulting Safety Policy.

The safety requirements for Yaskawa vendors performing work, such as put‐aways, within Yaskawa facilities are addressed in SAF‐P‐4004, Yaskawa Vendor Safety Policy.

Safety requirements for other visitors and guests are addressed in SAF‐P‐4001, Yaskawa Guest and Visitor Safety Policy.

Responsibilities

EHS Department

- Develop, administer, and update the Contractor Safety Program

- Develop and provide Contractor Safety Training Program

- Maintain list of Contractor and Subcontractor Trained Employees

- Review, approve, reject Contractor Approval packages (including annual renewal packages)

Facilities

- Obtain Contractor Approval packages prior to approval for entry to SAP

- Obtain Contractor Approval packages for contractors existing in SAP at time of Policy issue.

- Obtain annual renewal application for all approved contractors.

Approved General Contractors

- Provide a list of subcontractors

- Ensure all subcontractors satisfy all of the requirements of this policy.

All Yaskawa Associates

- Use only approved contractors that are in SAP.

- For contractors not in SAP, submit request for approval to Director, Facilities prior to any contracts being awarded.

Contractor Approval Process

Contractors shall be entered into SAP as an approved vendor only after they have satisfied all requirements detailed in this procedure.

Contractors shall provide Yaskawa with the following:

| Requirement |

Construction |

Service |

| Contractor Approval Checklist (SAF-F-4000) |

√ |

√ |

| Contractor Hold Harmless Agreement (SAF-F-4004) |

√ |

√ |

| Certificates of Insurance for Workers Compensation & Liability |

√ |

√ |

| OSHA 300 Logs for past 3 Years |

√ |

|

| Hazards Communication Policy |

√ |

√ |

| Blood Borne Pathogen Policy |

√ |

√ |

| Accident and Near Miss Reporting Policy |

√ |

√ |

| Alcohol and Drug Policy (must include reference to use of prescription and over the counter drugs) |

√ |

√ |

| Use of Cell Phone Policy |

|

√ |

| Electrical Safety Policy |

√ |

√ |

| Lock-Out/Tag-Out Policy |

√ |

√ |

| Fall Prevention Policy |

√ |

|

| Industrial Truck Operations Policy |

√ |

√ |

| Hearing Conservation Policy |

√ |

√ |

| Welding, Cutting, Brazing Policy (where applic.) |

√ |

√ |

Minimum Contractor Insurance Coverage

Contractor shall submit certifices of insurance annually.

| Description of Coverage |

Coverage Minimum |

| Workers Compensation |

Statutory |

| Employers Liability |

$500,000 Each occurrence |

| Comprehensive General Liability |

$2,000,000 Combined single limit bodily injury and property damage |

• An umbrella or excess liability policy may be used to increase the basic limits to the required levels

Contractor Employee Safety Orientation

After a contractor (company) has been approved, each contracted employee must complete appropriate safety orientation for each site in which he/she performs work.

After initial successful completion of the site safety orientation, the contracted employee will be considered authorized to perform work within that facility for one year or when significant policy changes occur, whichever comes first.

The EHS Risk Mitigation Manager and Yaskawa site representatives shall develop and maintain a contractor safety training program that includes, at a minimum, the following requirements:

- Smoking Policy

- Parking lot speed limit and parking restrictions

- Requirement for contractors to maintain a clean and orderly work area

- Zero tolerance for Harassment

- Zero tolerance for Alcohol and Drug Use

- Cell phone policy

- Emergency response information

- Process for reporting accidents and near misses

- Requirements for submitting Contractor Declaration of Hazardous Chemicals and SDS Submittal Form prior to any chemical being brought into

the facility

- Personal Protection Equipment (PPE) requirements

- Lock‐Out/Tag‐Out requirements

- Requirements for completing and submitting Job Hazard Assessment form

- Submission of Permits for performing any of the following:

- Hot Work

- Confined Space Entry

- Lock‐Out/Tag‐Out

- Ladders

- Scaffolding

- Rigging

- Use of Powered Industrial Trucks

- Use of Aerial and Scissor Lifts

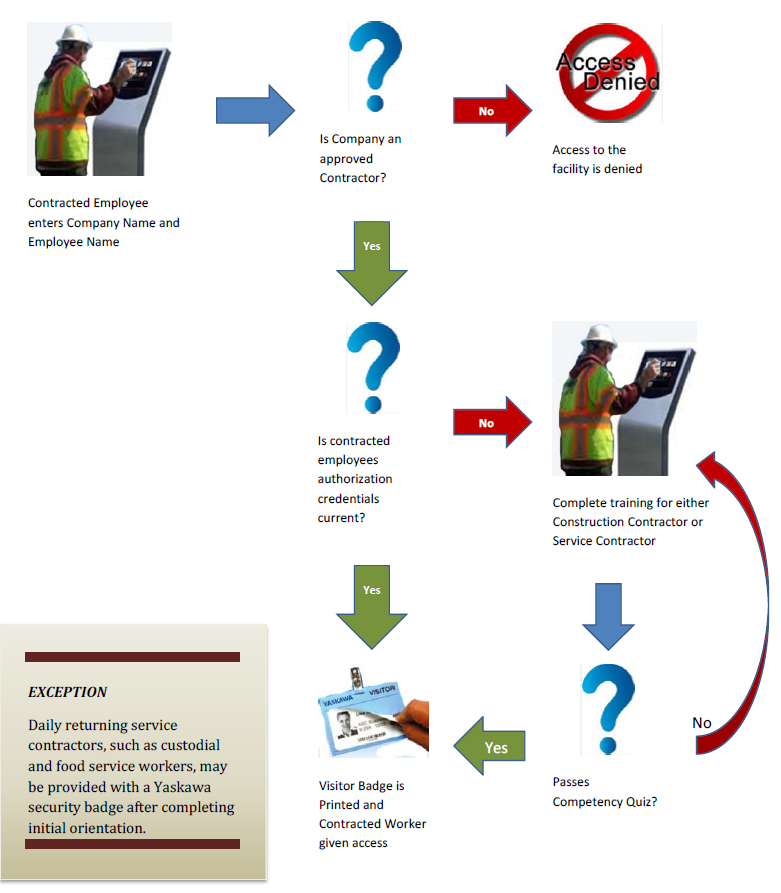

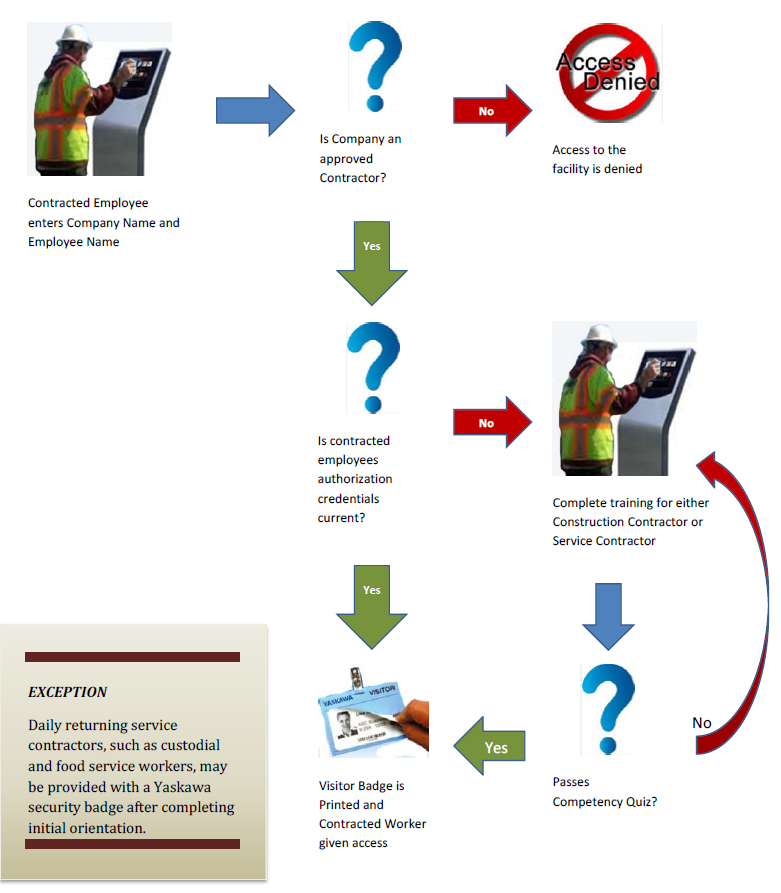

The following flowchart illustrates how the Contracted Employee Orientation program works:

Withdrawing Approval for a Contractor, Subcontractor, or Employee/designee of Contractor

Yaskawa America, Inc. reserves the right to terminate any approved contractor for failure to comply with site rules and regulations and/or to correct unsafe conditions or practices.

Yaskawa America, Inc. holds the contractor responsible for work performed by subcontractors.

- Contractors are responsible for ensuring subcontractors satisfy all of the requirements of this policy.

- Contractors are responsible for supervising subcontractors to ensure adherence to this policy and all site rules and regulations.

- Yaskawa America, Inc. reserves the right to deny subcontractors access to any Yaskawa site for failure to comply with site rules and regulations and/or to correct unsafe conditions or practices. Should this occur, the contractor is responsible for ensuring the work designated to the subcontractor is completed without additional time or cost to the approved contract/purchase order.

In some cases, an employee of a contractor may be denied access to a Yaskawa site without affecting Yaskawa’s relationship with the contractor company. In this instance, the employee’s name will be flagged as unauthorized in the contractor database.

Contractors shall not allow any person to sign in to a Yaskawa site using the credentials of another person. Doing so may result in immediate termination of the contractor.

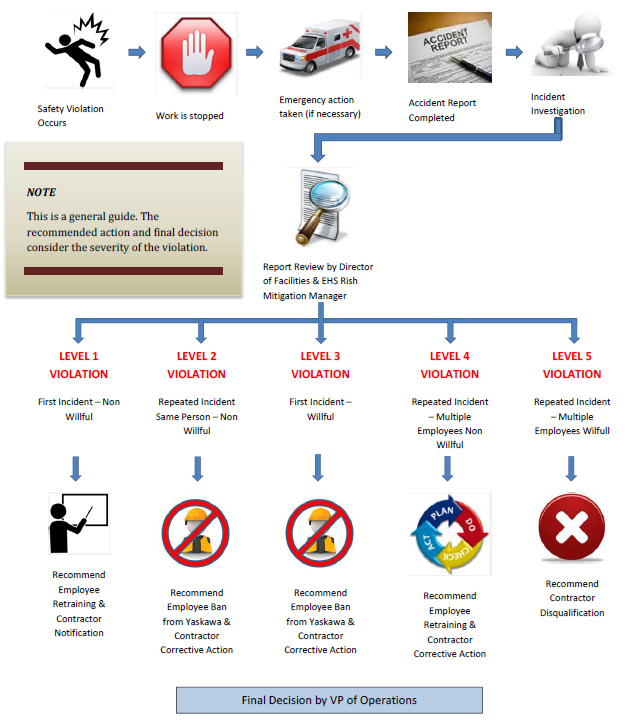

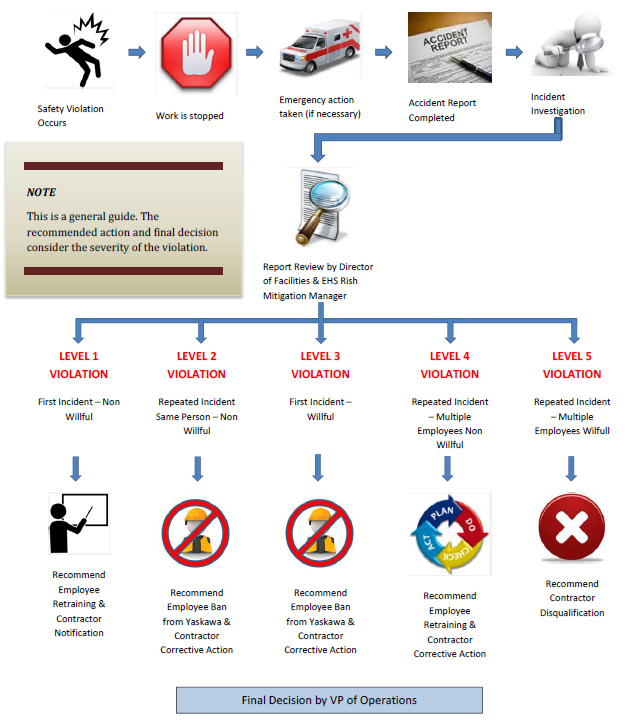

When a violation does occur, the Director of Facilities and the EHS Risk Mitigation Manager will review the details of the violation and make a recommendation to the Vice President of Operations who will make the final decision to either retrain or sever the relationship with the offender or contractor.

A contractor, subcontractor or employee of either, who is disallowed in one Yaskawa site is disallowed in all Yaskawa sites.

Upon correction of the deficiency and approval by the Vice President of Operations, the contractor may be reinstated to the Approved Contractor List.

Yaskawa America, Inc. reserves the right to terminate any agreement according to the terms and conditions of such agreement.

The following decision tree illustrates the process that shall be followed whenever a violation of this policy or site rules and regulations occurs:

Job Hazard Assessments

Construction Contractors

Prior to performing any work, the Contractor Forman or lead person shall complete a Contractor Job Hazard Assessment Form.

A copy of this form shall be sent to the EHS Risk Mitigation Manager.

The contractor shall review the Job Hazard Assessment Form with the supervisor of the area in which work is being performed.

The supervisor shall post a copy of the Job Hazard Assessment Form near

Service Contractors

Upon initial contract acceptance, the service contractor shall complete a Contractor Job Hazard Assessment form.

This form shall be valid for the duration of the contract unless new hazards are identified, at which time when the original form shall be obsolete and a new Job Hazard Assessment Form completed.

A copy of the Contractor Job Hazard Assessment Form shall be submitted to the EHS Risk Mitigation Manager.

The EHS Risk Mitigation Manager shall review the form and determine any action that needs to be taken to adequately inform associates of the hazards

present.

Declaration of Hazardous Chemicals

No contractor shall bring a hazardous chemical into any Yaskawa facility without first submitting the Contractor Declaration of Hazardous Chemicals and SDS Submittal Form and attaching associated Safety Data Sheets.

The form with attached Safety Data Sheets shall be emailed to EHS@Yaskawa.com.

The EHS Risk Mitigation Manager, or designee, shall enter the SDS into the SDS database.

A copy of the form with attached SDS’s shall be given to the supervisor of the area where the chemical will be used. The supervisor will review the hazards with affected associates in the area.

Reporting of Accidents and Near-Misses

Immediately following an accident (injury or property damage) or near miss (event that could have caused an accident), all work shall be halted and the supervisor of the area notified.

The supervisor shall interview the contracted employee and complete the First Report of Incident form. This shall be submitted to HR and the EHS Risk Mitigation Manager.

Work shall not resume until one of the following people review the incident form, investigate the scene, and approve work continuation:

- EHS Risk Mitigation Manager

- Director, Facilities

- Director, Operations

- Director, Quality & Engineering

A copy of the First Report of Incident Form will be sent to the Contractor.

The contractor shall investigate the scene and complete a corrective action report in all instances that lead to:

- Injury to Yaskawa associate or guest,

- Near miss where a Yaskawa associate or guest may have been injured,

- Property damage in excess of $500

- OSHA recordable injury to contracted employee

Revision History

| Rev # |

Description |

Release Date |

Approved by |

| 1 |

Initial Release |

6/12/2016 |

Thurwanger |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Program Review

| Review Date |

Reviewed by |

Changes Required (Yes/No) |

Revision # if updated |

| 2/15/2017 |

Thurwanger |

No |

|

| 1/10/2018 |

Thurwanger |

No |

|

| 1/17/2019 |

Thurwanger |

No |

|

| 1/9/2020 |

Thurwanger |

No |

|

| 1/19/2021 |

Thurwanger |

No |

|

| 1/13/2022 |

Thurwanger |

No |

|

| 1/26/2023 |

Thurwanger |

No |

|

| 1/11/2024 |

Thurwanger |

No |

|

| 1/16/2025 |

Thurwanger |

No |

|

|

|

|

|