Policy Index

Overview

Responsibilities

General Crane Safety Rules

Crane, Hoist, and Rigging Inspection

Operator Qualifications

Design Requirements

Crane & Hoist Operation

Rigging

Standard Hand Signals

Records and Forms

Training

Danger of Compressed Gas Video

Policy

Overview

Many types of cranes, hoists, and rigging devices are used within Yaskawa America, Inc. for lifting and moving materials.

YAI’s policy is to maintain a safe workplace for its associates; therefore, it cannot be overemphasized that only qualified individuals shall operate these devices.

The safety rules and guidance in this policy apply to all activities that involve the use of cranes and hoists installed in or attached to buildings and to all YAI associates, supplemental labor, and subcontractor personnel who use such devices.

Many types of cranes, hoists, and rigging devices are used within Yaskawa America, Inc. for lifting and moving materials.

YAI’s policy is to maintain a safe workplace for its associates; therefore, it cannot be overemphasized that only qualified individuals shall operate these devices.

The safety rules and guidance in this policy apply to all activities that involve the use of cranes and hoists installed in or attached to buildings and to all YAI associates, supplemental labor, and subcontractor personnel who use such devices.

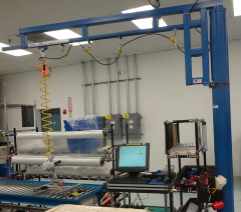

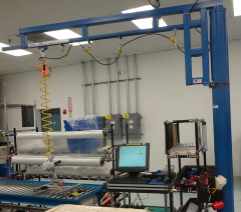

Jib Crane and Hoist

Responsibilities

Cost Center Managers

Cost Center Managers of department in which crane and hoist equipment is located is responsible for:

- Performing (or coordinating) annual maintenance and inspection of all cranes and hoists within their cost center.

Conducting or coordinating special load tests of cranes and hoists.

- Maintaining written records of inspections and tests.

- Inspecting and load testing cranes and hoists following modification or extensive repairs (e.g., a replaced cable or hook, or structural modification).

- Scheduling a non-destructive test and inspection for crane and hoist hooks at the time of the annual load test, and testing and inspecting before use new replacement hooks and other hooks suspected of having been overloaded. The evaluation, inspection, and testing may include, but are not limited to visual, dye penetrate, and magnetic particle techniques referenced in ASME B30.10 (Hooks, Inspection and Testing).

- Maintaining all manuals for cranes and hoists in a central file for reference.

Supervisors

Supervisors are responsible for:

- Ensuring associates under their supervision receive the required training and are certified to operate the cranes and hoists in their areas of responsibility.

- Providing training for prospective crane and hoist operators.

- Evaluating crane and hoist trainees.

- Ensuring that hoisting equipment (crane, hoist, rigging) is inspected and tested daily (or prior to each use for hoisting equipment that is not used daily) by a responsible individual.

Crane Operators

Crane and Hoist operators are responsible for:

- Operating hoisting equipment safely.

- Conducting functional tests prior to using the equipment.

- Selecting and using rigging equipment appropriately.

General Crane Safety Rules

Operators shall comply with the following rules while operating cranes and hoists:

- Do not engage in any practice that will divert your attention while operating the crane.

- Respond to signals only from the person who is directing the lift, or any appointed signal person.

- An Emergency Stop signal must be obeyed immediately regardless of who gives it. Standard "Stop" signals are typically directed by the assigned signal personnel.

- Do not move a load over people

- People shall not be placed in jeopardy by being under a suspended load.

- Also, do not work under a suspended load unless the load is supported by blocks, jacks, or a solid footing that will safely support the entire weight. Have a crane or hoist operator remain at the controls or lock open and tag the main electrical disconnect switch.

- Ensure that the rated load capacity of a crane's bridge, individual hoist, or any sling or fitting is not exceeded. Know the weight of the object being lifted.

- Check that all controls are in the OFF position before closing the main-line disconnect switch.

- If spring-loaded reels are provided to lift pendants clear off the work area, ease the pendant up into the stop to prevent damaging the wire.

- Avoid side pulls.

- These can cause the hoist rope to slip out of the drum groove, damaging the rope or destabilizing the crane or hoist. The load should always be directly below the hoist.

- To prevent shock loading, avoid sudden stops or starts.

- Shock loading can occur when a suspended load is accelerated or decelerated, and can overload the crane or hoist. When completing an upward or downward motion, ease the load slowly to a stop.

Crane, Hoist, and Rigging Inspection

All tests and inspections shall be conducted in accordance with the manufacturers recommendations.

Daily Inspections

All cranes shall be inspected on each shift in which they are used prior to operating the crane on that shift.

There are three categories of cranes for the purpose of this inspection requirements: Daily Use Cranes, Occasional Use Cranes, and Out-of-Service Cranes.

Daily Use Cranes are those cranes that are frequently used. The inspection will occur each shift on which they are frequently use.

Occasional Use Cranes are only inspected on the shifts on which they are used. They do not require inspection on days in which they are not used. Once the inspection is complete and passed all inspection points, the crane can be used for the remainder of the shift without additional inspection (unless other factors indicate another inspection is required.)

Out-of-Service Cranes are removed from service and locked out in a manner that prevents unplanned operation. Out-of-Service cranes must be inspected by Manufacturing Engineering or other competent authority before the crane can be returned to service.

The daily/shift test shall include, as applicable:

- Test the upper-limit switch. Slowly raise the unloaded hook block until the limit switch trips.

- Visually inspect the hook, load lines, trolley and bridge as much as possible from the ground.

- If provided, test the lower limit switch.

- Test all direction and speed controls for both bridge and trolley travel.

- Test all bridge and trolley limit switches, where provided, if operation will bring the equipment in close proximity to the limit switches.

- Test the pendant emergency stop.

- Test the hoist brake to verify there is no drift without a load.

- Inspect the hook for signs of damage. Inspect the safety latch.

- Inspect slings for signs of wear.

Annual Inspections

The cost center manager of the department that has responsibility for the crane shall coordinate with an authorized inspector to perform the annual inspection.

The inspection shall include, as applicable:

- Hoisting and lowering mechanisms.

- Trolley travel or monorail travel.

- Bridge travel.

- Limit switches and locking and safety devices.

- Structural members.

- Bolts and rivets.

- Sheaves and drums.

- Parts such as pins, bearings, shafts, gears, rollers, locking devices, and clamping devices.

- Brake system parts, linings, pawls, and ratchets.

- Load, wind, and other indicators over their full range.

- Power plants.

- Chain-drive sprockets.

- Crane and hoist hooks.

- Electrical apparatus such as controller contractors, limit switches, and push button stations.

- Wire rope.

- Hoist chains.

- Rails.

Load Testing

Load testing shall only be performed by authorized contractor or Professional Mechanical Engineer.

- Newly installed cranes and hoists shall be load tested to no greater than 125% the rated capacity.

- Slings shall have appropriate test data when purchased. It is the responsibility of the cost center manager requisitioning the slings to ensure that the appropriate test data are obtained and maintained.

- Re-rated cranes and hoists shall be load tested to no greater than 125% of the new capacity if the new rating is greater than the previous rated capacity

- Fixed cranes or hoists that have had major modifications (including moving the crane) or repair shall be load tested to no more than 120% of the rated capacity

- Cranes and hoists that have been overloaded shall be inspected prior to being returned to service.

- Personnel platforms, baskets, and rigging suspended from a crane or hoist hook shall be load tested initially, then re-tested annually thereafter

Operator Qualifications

All workers who use any Yaskawa America, Inc. crane shall be qualified.

To be qualified as a crane and hoist operator, the associate shall:

- Complete Yaskawa crane and hoist safety education, and

- Have received hands-on training from a qualified crane and hoist trainer.

- Upon successful completion of training, the associates competency record shall be updated.

Levels of Qualification

Overhead Crane Safety Awareness Training

This training is provided to all associates who may work in areas where overhead cranes are operated.

Overhead Crane Qualified < 5 Ton

This certification must be obtained for associates who operate overhead cranes that are less than or equal to 5 tons. These cranes are generally used in production and warehouse areas.

Overhead Crane Qualified 5 Ton to 10 Ton

Cranes that are greater than 5 ton are often controlled by a variable frequency drive and require a higher level of certification. Cranes in this category can be found at the CT cleanroom and in the laboratories.

There are two types of certification in this category: 1) Specific Use, and 2) General Use.

Specific use certification is granted when an associate is qualified to use the crane for specific purposes - such as lifting the CT plate, but the associate is not qualified to use the crane to lift items for which they have not been specifically qualified.

General use certification is used when the associate is competent to perform critical lift plans and safely use the crane to any loads within the rated capacity.

Overhead Crane Qualified > 10 ton

This qualification is required for associates operating cranes greater than 10 tons, such as the bridge crane in the Franklin facility. This VFD controlled crane has specific training requirements that are not included in the lower category training.

There are two types of certification in this category: 1) Specific Use, and 2) General Use.

Specific use certification is granted when an associate is qualified to use the crane for specific purposes - such as lifting and moving a Medium Voltage Drive, but the associate is not qualified to use the crane to lift items for which they have not been specifically qualified.

General use certification is used when the associate is competent to perform critical lift plans and safely use the crane to any loads within the rated capacity.

Design Requirements

- The design of all cranes and hoists used within Yaskawa facilities shall comply with the requirements of ASME/ANSI B30 standards and Crane Manufacturer’s Association of America standards (CMAA-70 and CMAA-74).

- All crane and hoist hooks shall have safety latches.

- Hooks shall not be painted (or repainted) if the paint previously applied by the manufacturer is worn.

- Crane pendants shall have an electrical disconnect switch or button to open the main-line control circuit.

- Cranes and hoists shall have a main electrical disconnect switch. This switch shall be labeled with lockout capability.

- Crane bridges and hoist monorails shall be labeled on both sides with the maximum capacity.

- Each hoist-hook block shall be labeled with the maximum hook capacity.

Crane & Hoist Operation

Personal Protective Equipment

- Hard Hats: A Type 2 (provides protection to top and side of head) Class A (voltage protection up to 2,200 volts) hard hat or helmet shall be worn:

- Franklin DVAF Facility - whenever operating an overhead crane or within the load fall zone

- All other Facilities - whenever operating an overhead crane when the load is above chest level

- Safety glasses with side shields

- Safety shoes with toe protection

Moving a Load

Center the hook over the load to keep the cables from slipping out of the drum grooves and overlapping, and to prevent the load from swinging when it is lifted.

- Inspect the drum to verify that the cable is in the grooves.

Plan and check the travel path to avoid personnel and obstructions.

Lift the load only high enough to clear the tallest obstruction in the travel path.

Start and stop slowly.

Land the load when the move is finished. Choose a safe landing.

Never leave suspended loads unattended.

- In an emergency where the crane or hoist has become inoperative, if a load must be left suspended, barricade and post signs in the surrounding area, under the load, and on all four sides. Lock open and tag the crane or hoist’s main electrical disconnect switch.

Parking a Crane or Hoist

Remove all slings and accessories from the hook. Return the rigging device to the designated storage racks.

Raise the hooks at least 7 feet above the floor.

Store the pendant away from aisles and work areas, or raise it at least 7 feet above the floor.

Place the emergency stop switch (or push button) in the OFF position.

Rigging

General Requirements

Only select rigging equipment that is in good condition. All rigging equipment shall be inspected annually.

The load capacity limits shall be stamped or affixed to all rigging components.

A minimum safety factor of 5 shall be maintained for wire rope slings (rated for at least 5-times the load weight).

Defective equipment is to be removed from service and destroyed to prevent inadvertent reuse.

Rigging Defects

Rigging with the following defects shall be rejected and destroyed to prevent accidental use.

Nylon slings with:

- Abnormal wear

- Torn stitching

- Broken or cut fibers

- Discoloration or deterioration

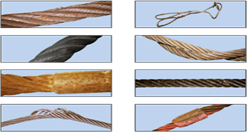

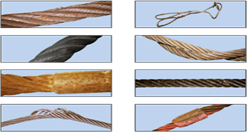

Wire rope slings with:

- Kinking, crushing, bird-caging, or other distortions

- Evidence of heat damage

- Cracks, deformation, or worn end attachments

- Six randomly broken wires in a single rope lay

- Three broken wires in one strand or rope

Hooks:

- Opened more that 15% at the throat

- Twisted sideways more than 10 degrees from the plane of the unbent hook

Alloy Steel Chain Slings with:

- Cracked, bent, or elongated links or components

- Cracked hooks

- Shackles, eye bolts, turnbuckles, or other components that are damaged or deformed

Rigging the Load

Do the following when rigging a load:

- Determine the weight of the load. Do not guess.

- Determine the proper size for slings and components.

- Do not use manila rope for rigging.

- Make sure that shackle pins and shouldered eye bolts are installed in accordance with the manufacturer’s recommendations.

- Make sure that ordinary (shoulderless) eyebolts are threaded in at least 1.5 times the bolt diameter.

- Use safety hoist rings (swivel eyes) as a preferred substitute for eyebolts wherever possible.

- Pad sharp edges to protect slings. Wood, tire rubber, or other pliable materials may be suitable for padding.

- Do not use slings, eyebolts, shackles, or hooks that have been cut, welded, or brazed.

- "Job-made" rigging is prohibited. Only forged, certified, and rated hardware from recognized manufacturers is permitted.

- Install wire-rope clips with the base only on the live end and the U-bolt only on the dead end. Follow the manufacturer’s recommendations for the spacing for each specific wire size.

- Determine the center of gravity and balance the load before moving it.

- Initially lift the load only a few inches to test the rigging and balance.

Standard Hand Signals

When the crane operator’s view is partially or fully obstructed, additional qualified workers provide direction through standard hand signals and voice communication.

Emergency Stop

Emergency Stop

Arms stretched out (like baseball "safe" signal), then forearms brought to chest. Follow all Emergency Stop signals, regardless of who gives it.

Standard Stop

Standard Stop

One arm stretched out then forearm brought to chest.

Hoist

Hoist

With forearm vertical, forefinger pointing up, move hand in small horizontal circles.

Lower

Lower

With arm extended downward, forefinger pointing down, move hand in small horizontal circles.

Bridge Travel

Bridge Travel

Arm extended forward, hand open and slightly raised, make pushing motion in direction of travel.

Trolley Travel

Trolley Travel

Palm up, fingers closed, thumb pointing in direction of motion, jerk hand horizontally.

Move Slowly

Move Slowly

Use one hand to give desired motion signal and place the other hand motionless above the hand giving the motion signal.

Multiple Trolleys

Multiple Trolleys

With multiple trolley cranes, used to indicate which hoist is being referenced. Hold up one finger for block marked "1" and two fingers for block marked "2". Regular hand signals follow.

Records and Forms

| Record Title |

Retained by |

Disposition |

| Daily Crane, Hoist, Sling Inspection |

Cost Center Manager |

Retain for 5 years (min) |

| Annual Crane, Hoist, Sling Inspection and Load Test |

Cost Center Manager |

Retain for 5 years (min) |

| Initial Crane/Hoist Certification (Also includes move or modification of existing crane) |

Cost Center Manager |

Retain for life of equipment |

| Crane Operator Qualification |

Associate’s Supervisor |

Retain for employment tenure plus 3 years (min) |

Training

Generalized crane and hoist awareness and policy training is provided to all associates within the first 90-days of employment.

Associates who work near cranes and hoists shall receive instruction from their supervisor indicating qualification requirements prior to being exposed to the affected work area.

Crane and Hoist Qualification Training shall be successfully completed prior to operating a crane/hoist.

Crane and Hoist Qualification - Supervisor Hands-On Training shall be successfully completed prior to operating a crane/hoist.

Records of this training shall be retained by the associate's supervisor.

External Resources

Video:

Lifting Safely. Cranes, Hoists, and Rigging

Revision History

| Rev # |

Description |

Release Date |

Approved by |

| 0 |

Conversion of old safety documents, rewrite, and issue |

4/11/2016 |

Thurwanger |

| 1 |

Added Standard Hand Signals |

2/12/2019 |

|

| 2 |

Added Crane and Hoist Safety Design Requirements |

2/8/2023 |

|

| 3 |

Added Crane Assembly and Disassembly |

3/26/2025 |

|

|

|

|

|

|

|

|

|

Program Review

| Review Date |

Reviewed by |

Changes Required (Yes/No) |

Revision # if updated |

| 2/15/2017 |

Thurwanger |

No |

|

| 1/10/2018 |

Thurwanger |

No |

|

| 1/17/2019 |

Thurwanger |

Yes |

1 |

| 1/9/2020 |

Thurwanger |

No |

|

| 1/19/2021 |

Thurwanger |

No |

|

| 1/13/2022 |

Thurwanger |

No |

|

| 1/26/2023 |

Thurwanger |

Yes |

2 |

| 1/11/2024 |

Thurwanger |

No |

|

| 1/16/2025 |

Thurwanger |

Yes |

3 |

| 2/11/2026 |

Thurwanger |

No |

|