Policy Key Points

Policy

Introduction

Yaskawa associates shall be trained and qualified by their supervisor prior to operating any power tool.

Qualification shall be documented for operators of grinders and power saws.

Machine Guarding

No associate shall operate and/or cause to be operated any machinery without proper protective guards in place or modify/disable any protective guards on machinery without contacting Environmental Health and Safety for such approval.

Guards shall be provided to protect the machine operator and other people from hazards such as:

- exposed belts,

- pulleys, sheaves,

- drive shafts,

- drive couplings,

- chains,

- keyed motor shafts,

- rotating parts,

- flying chips, and

- sparks.

Machine Guarding Responsibilities

EHS is responsible for:

- Inspecting machines for appropriate guarding during safety inspections, while performing Job Hazard Assessments, or as requested.

- Reporting any questionable conditions that are discovered to the responsible department, and

- Investigating injuries related to machine guarding.

Department Managers are responsible for:

- Contacting EHS for approval of alternative guarding methods,

- Inspecting new and existing equipment to ensure proper guards are in place,

- Equipment manufacturers often sell equipment that does not meet OSHA guarding requirements instead offering these as options. Managers must make sure that any purchased equipment has all required guards.

- Implementing engineering controls as deemed necessary,

- Facilitating equipment specific training with regard to machine guarding,

- Ensuring those associates who need to modify/disable any protective guards are Lockout/Tagout Authorized.

- Ensuring all tagged “out-of-service” tools/equipment are replaced appropriately.

Associates are responsible for:

- Complying with all aspects of this program,

- Ensuring they are competent in using the tools or equipment,

- Reporting all damaged or malfunctioning tools/equipment to their supervisor and removing or tagging such tools/equipment as “out of service”

Grinders

All guards must remain in place.

The RPM of the wheel shall always exceed the RPM of the grinder on which its used.

Under no circumstances shall repairs be performed by unqualified personnel on damaged or defective grinders.

Soft metals, such as aluminum, are not to be ground on general purpose wheels.

Only associates who are documented as “grinder qualified” shall use a grinder. Qualified associates shall be responsible for its safe operating condition before putting it in use.

Shirttails must be tucked in and long sleeves buttoned while using grinders.

Associates shall always warn people in the immediate area before starting a grinder.

The following PPE is required when using a grinder:

- Safety Glasses

- Face Shield

- Ear plugs

- Steel-toed shoes

Deflection screens may be needed to protect personnel or other equipment.

When small items are to be ground, they should be placed in a vice.

All wheels and disk must be checked for wear before use.

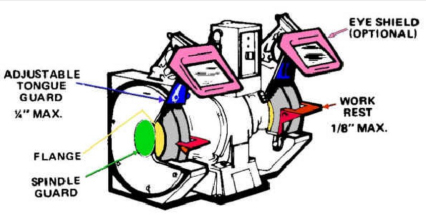

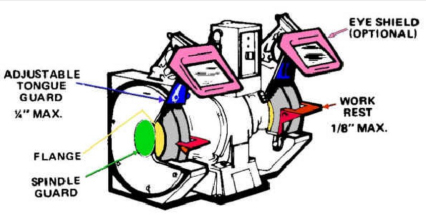

Bench and Pedestal Grinder Specific Requirements

Follow all of the General Requirements

Stand clear of wheels until grinder reaches maximum speed.

Do not grind on the side of wheels unless the grinding machine is designed for this express purpose.

Do not adjust the work rest while the wheel is in motion.

Do not use a wheel that is worn out of round until it is trued.

Portable Grinder Specific Requirements

Follow all of the General Requirements.

Portable grinders must be equipped with guards.

Angle grinders must have a handle attached if so designed by the manufacturer.

Operator must wear face shield and safety glasses.

The worker’s position for grinding must be such as to allow both hands to be placed firmly on the grinder. Never remove the handle from the grinder.

Never hold materials to be ground in one hand while grinding with the other.

When changing the grinding tool, always unplug the grinder.

Use some type of vise or clamping tool to firmly hold metal to be ground.

Damaged disks shall not be used. Disks with apparent damage shall be changed before use.

All portable grinders shall be equipped with a constant pressure control switch. Locking triggers are not allowed.

Tool Use Safety

General Requirements

Inspect all tools before using. Never use defective tools.

Use all tools only for their intended purpose.

Don’t force tools beyond their capacity.

Always leave safety guards on the tool. They are designed to keep you safe. Use them.

Tie long hair back and do not wear loose clothing when using rotary tools that could pull the operator into the tool operation

Know how to shut off a tool before turning it on.

Check area for other persons that could be harmed from operation of tool.

Store tools in a safe place when not in use.

Do not use tools with which you are not qualified.

Electric Power Tools

Electric power tools shall be of the double-insulated type or properly grounded.

The use of electrical cords for hoisting, lowering or carrying tools is not permitted.

Approved safety glasses shall be worn when using electric power tools.

Hand Tools

Wrenches shall not be used when jaws are sprung to the point that slippage occurs.

Impact tools shall be kept free from mushroomed heads.

The wooden handles of tools shall be kept free of splinters or cracks and shall be kept tight.

Pneumatic Power Tools

Pneumatic power tools shall be secured to the hose or whip by some positive means to prevent the tool from being accidently disconnected.

Non-metallic one-piece retaining pin and ring shall be used to secure sockets and accessories on pneumatic impact tools to prevent attachments from being accidentally expelled. The retaining ring should be securely taped in place.

Impact wrenches must be checked immediately before use to assure that the retaining pin, ring, and tape are securely in place.

The use of hoses for hoisting, lowering or carrying tools is not permitted.

All hoses exceeding ½” inside diameter shall have a safety device at the source of supply or branch line to reduce pressure in case of hose failure.

Results of Breaches of Policy

Breaching this policy may result in an injury. Breaches of this policy may result in disciplinary action being initiated in accordance with Yaskawa America's discipline policy.

Training

Yaskawa General Safety Training, located at www.YaskawaSafety.com, includes a module titled Equipment Requiring Certified Operators. All associates working in Production, Repair, and Maintenance areas are required to complete this training.

It is the responsibility of Yaskawa supervisors to ensure associates are trained in the proper use of tools within their work area. This training shall include potential hazards posed by the tool.

Revision History

| Rev # |

Description |

Release Date |

Approved by |

| 0 |

Conversion of old safety documents, rewrite, and issue |

5/19/2016 |

Thurwanger |

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Program Review

| Review Date |

Reviewed by |

Changes Required (Yes/No) |

Revision # if updated |

| 2/21/2017 |

Thurwanger |

No |

|

| 1/16/2018 |

Thurwanger |

No |

|

| 1/22/2019 |

Thurwanger |

No |

|

| 1/14/2020 |

Thurwanger |

No |

|

| 1/21/2021 |

Thurwanger |

No |

|

| 1/18/2022 |

Thurwanger |

No |

|

| 1/31/2023 |

Thurwanger |

No |

|

| 1/16/2024 |

Thurwanger |

No |

|

| 1/21/2025 |

Thurwanger |

No |

|

| 2/11/2026 |

Thurwanger |

No |

|