Policy Key Points

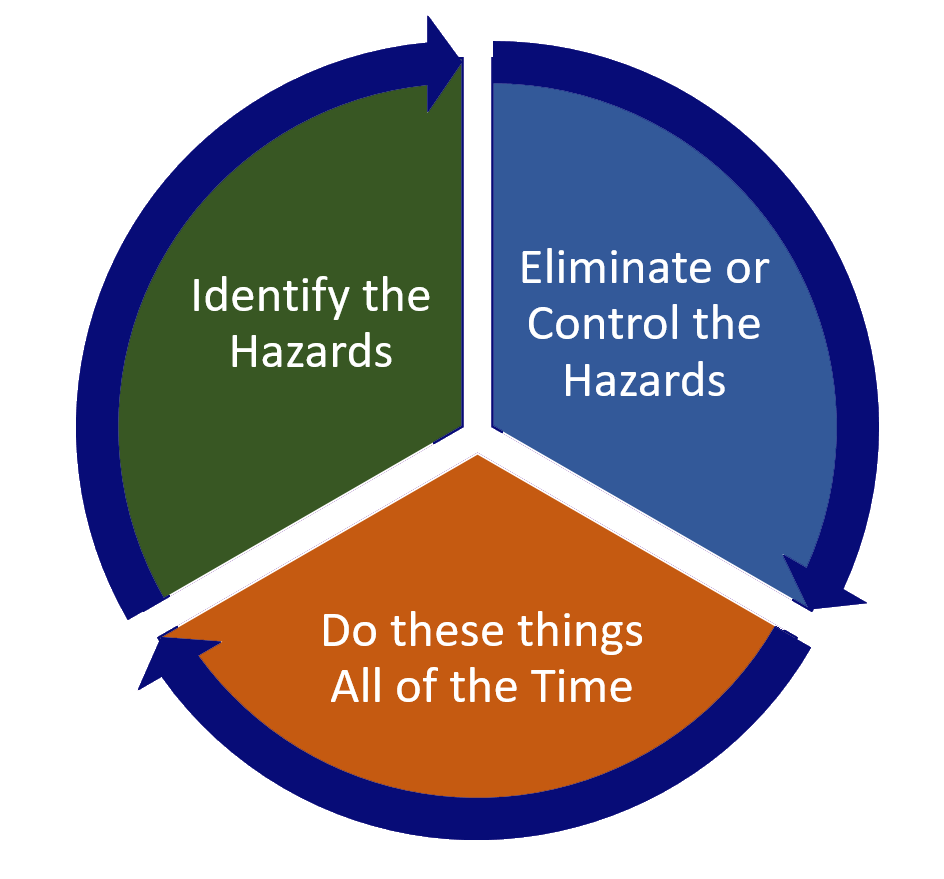

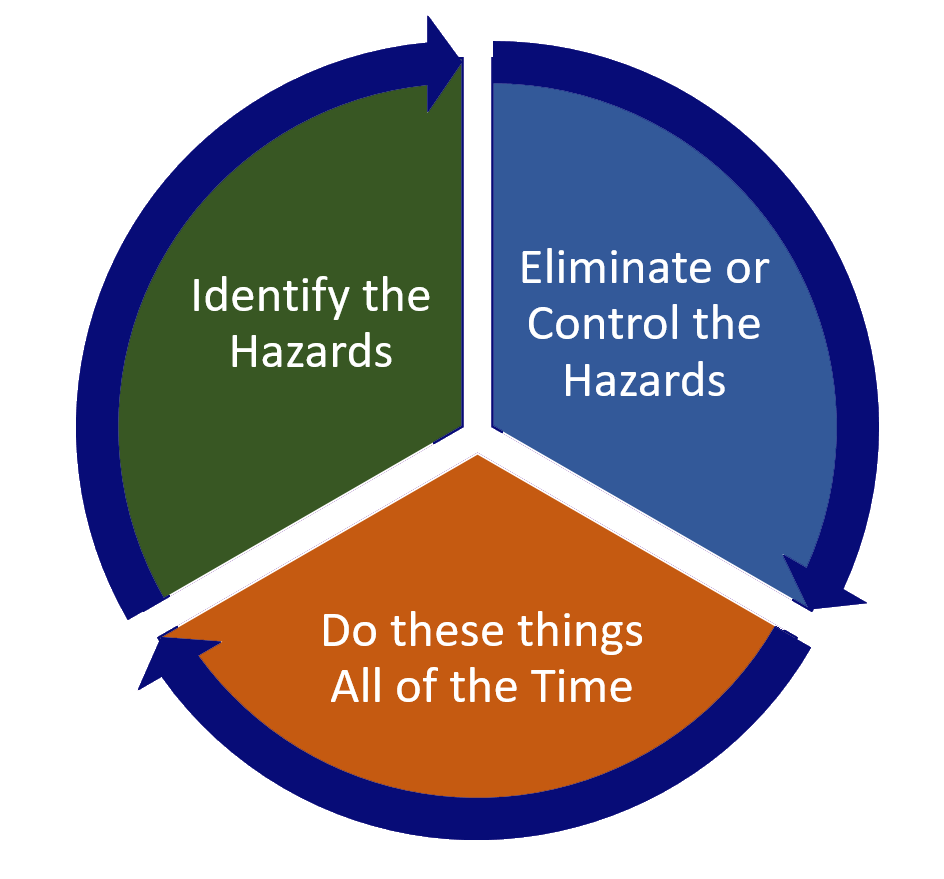

Safety is doing three things: 1) Identifying the Hazards, 2) Controlling the Hazards, and 3) Doing these things Always. This policy provides guidance on how a person can use a disciplined process to identify the hazards then use the Hierarchy of Controls to properly control the hazards.

Purpose and Scope of this Policy

Safety Triad

Within Yaskawa, safety is doing three things:

- Identifying the Hazards,

- Controlling the Hazards, and

- Doing these things Always

The purpose of this policy is to identify how we identify and control the hazards, and how we can make it easy for associates to do these things always.

The purpose of this policy is to illustrate how we:

- Identify the hazards,

- Notify appropriate people of the hazard,

- Analyze the risk posed by the hazard,

- Control the hazard, and

- Use accident signs and tags to communicate the hazards.

This policy applies to all associates in all locations.

Responsibilities

Each Associate's Direct Supervisor

- Identify the hazards in his/her area of responsibility,

- Take appropriate steps to eliminate or control the hazard using the hierarchy of controls,

- Provide training to associates about the hazards that they may encounter and the proper methods utilized to control them.

Each Associate

- Be aware of the hazards in his/her work area,

- Notify their supervisor if they identify an uncontrolled hazard, unsafe act, or unsafe condition,

- Follow all safety policies, instructions, and precautions (such as warning signs), and

- Ensure others do the same.

Environmental, Health, and Safety (EHS) Department

- Provide training to supervisors in proper methods of performing a risk assessment and proper controls using the hierarchy of controls,

- Assist supervisors as requested in completing the hazard assessment, and

- Conduct periodic audits to ensure compliance to Yaskawa Safety Policies.

Hazard Identification

Hazards can be identified by asking the following questions:

- What can go wrong?

- What are the consequences if something does go wrong?

- How could the hazard manifest into an incident?

- What are the contributing factors?

- How likely is it that the hazard will result in an injury or illness?

Good hazard scenarios describe:

- Where it is happening?(environment)

- Who or what it is happening to?(exposure)

- What precipitates the hazard (trigger)

- The outcome that may occur if it happens (consequence), and

- Any other factor

Rarely is an accident a simple case of one singular cause resulting in one singular event. More frequently, many contributing factors tend to line up in a certain way to create the hazard. Example:

In the metal shop (environment), while clearing a snag (trigger), a worker's hand (exposure) comes into contact with a rotating pulley. It pulls his hand into the machine and severs his fingers (consequence). The associate was wearing gloves at the time (contributing factor).

Macro Job Analysis

A macro analysis is a thorough analysis by job types that is used to identify hazards for new equipment or processes, or when changes occur to existing equipment or processes.

A macro analysis is typically performed by the Product Development, EHS department, Manufacturing Engineering, or the area supervisor. Affected associates and/or subcontractors shall be included in the risk analysis to gather their input, identify potential hazards that might otherwise be missed, and provide input into potential hazard controls.

The macro analysis should be completed:

- When a new product is being designed for manufacturing by Yaskawa,

- When a new process is introduced,

- When new equipment is installed,

- When changes are made to the product, process, or equipment, and

- Periodically thereafter based on the Risk Assessment Score.

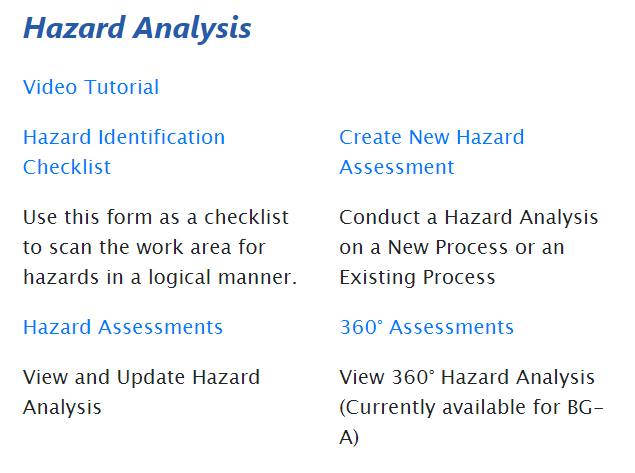

Prior to 2024, Macro Job Hazard Analyses were stored in a Microsoft Access database located on the facility G:\Safety network location. These are being converted into new JHA systems that are located at the safety website (www.YaskawaSafety.com/hazards.html) in two different formats.

- The first format is used to document a JHA for existing jobs until they are converted to the 360° format shown below. This method is also used for a short-term analysis - such as rework or when we perform a process that is rarely performed.

This method takes the reviewer through a logical process by identifying any actions that have the potential for a serious injury or fatality (SIF). Then, the reviewer looks at physical, chemical, ergonomic, environmental, and any other hazards.

- The second method is a 360° analysis giving the viewer the opportunity to see the hazards in the work area and how they are to be controlled.

If the worker identifies any hazards that are not shown in the 360° analysis, they must report the new hazard immediately to their supervisor.

Hazard Menu

Located at www.YaskawaSafety.com/hazards.html

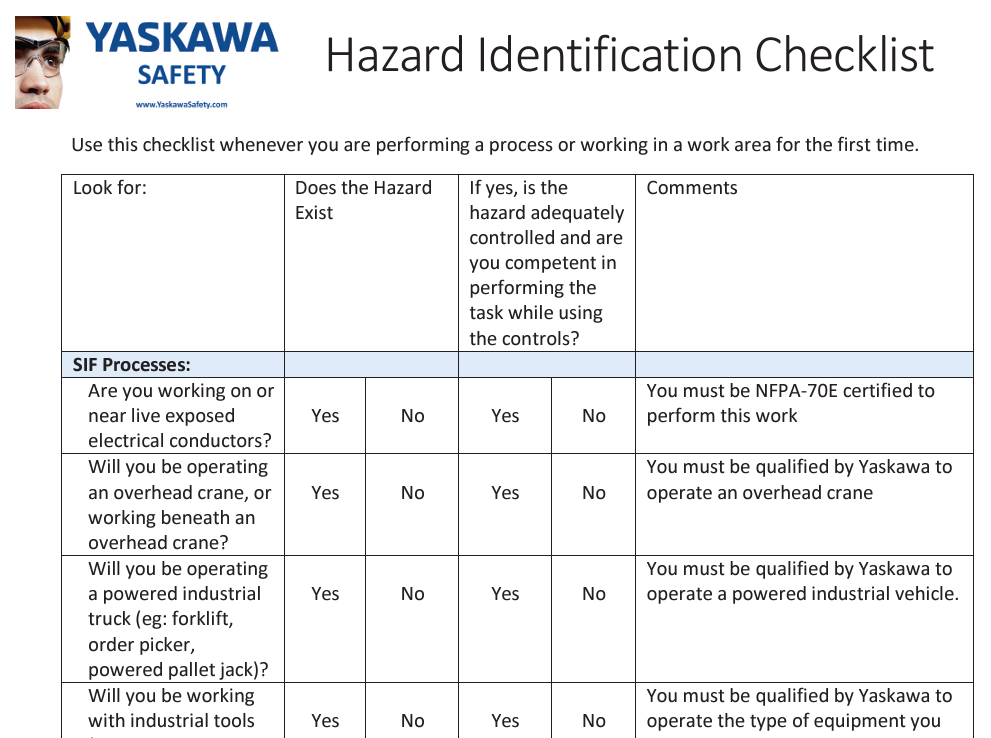

Hazard Identification Checklist

Previous Next

Click on the left or right side of the image to scroll through the images

Micro Hazard Analysis

A micro hazard analysis occurs every day and throughout the day. The worker scans the area to identify the hazards and makes sure they are sufficiently controlled.

There are two ways to perform a micro hazard analysis:

- One tool is the 2 minute and 10 second analysis where the worker takes approximately 2 minutes at the start of their shift and after extended breaks to analyze hazards at the station. Through the day, the worker takes 10 seconds to analyze the hazards with each new task.

- Another method is to use the Hazard Identification Checklist (link to the checklist). This check sheet walks through potential hazards with a series of questions in each of the following categories:

- Hazards that have the potential to lead to a serious injury or fatality (SIF),

- Physical hazards (such as fall and struck-by hazards),

- Chemical hazards, and

- Physical movement

Hazard Notification

If an identified hazard cannot be immediately controlled (such as cleaning up a spill), the associate who identifies the hazard must immediately notify their supervisor, another member of management, or the EHS department (EHS@Yaskawa.com or 262-391-1697).

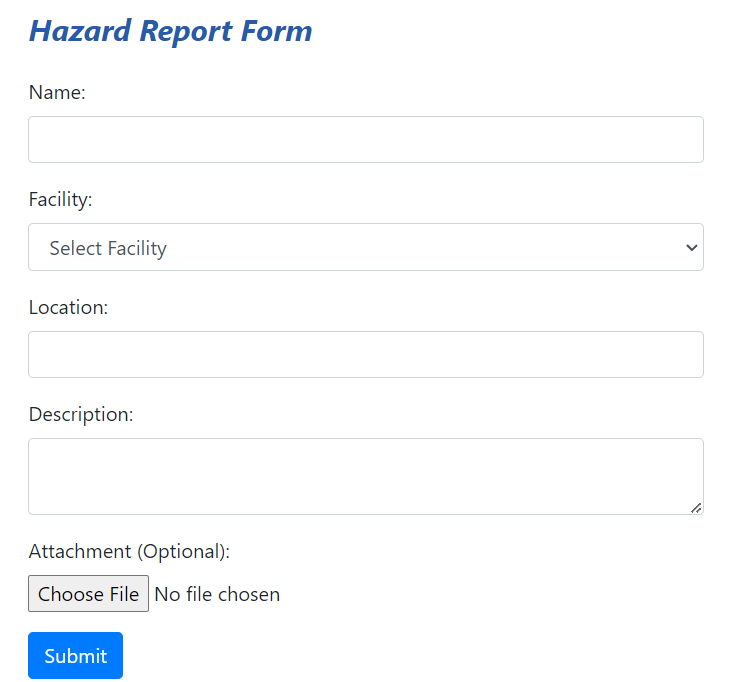

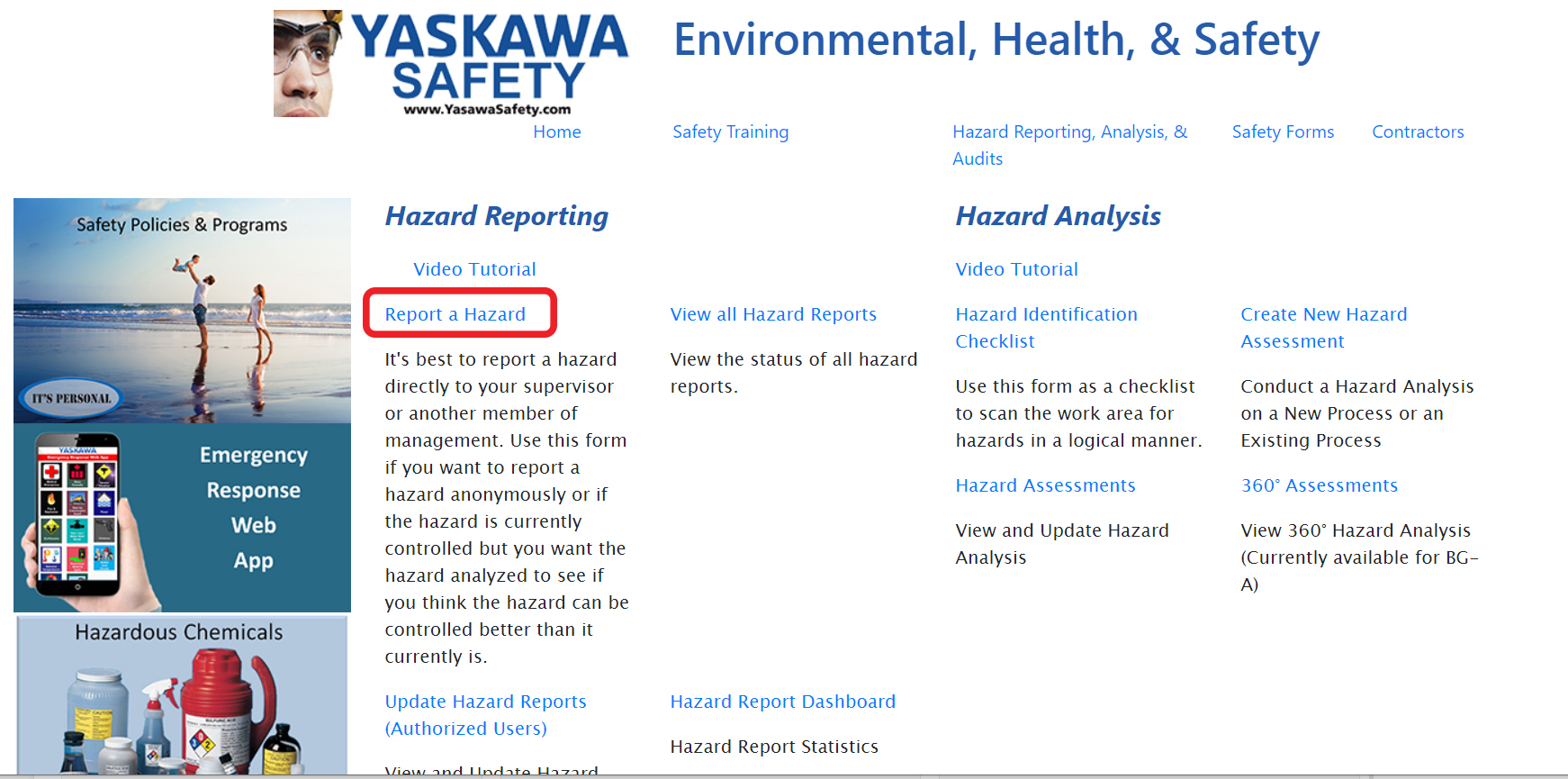

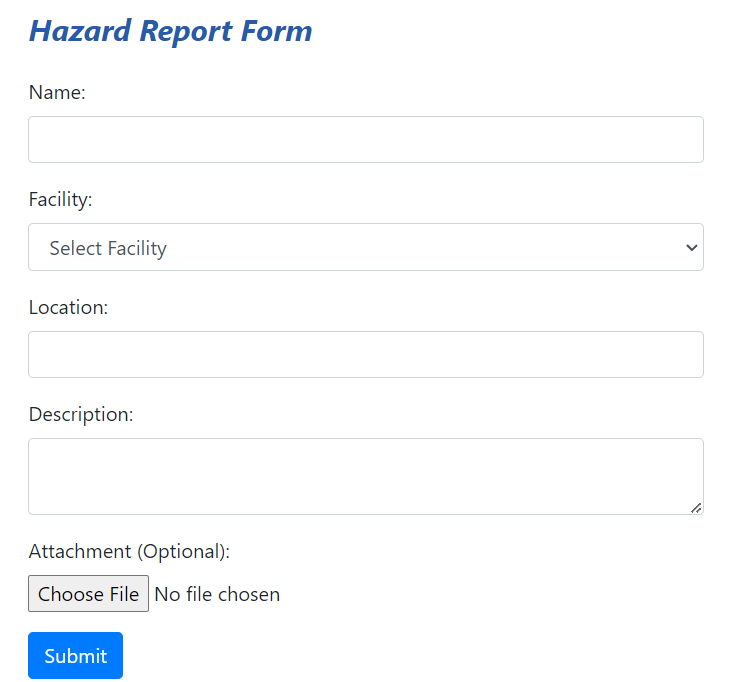

If an associate wants to report a hazard anonymously, or if the control cannot be immediately implemented, the hazard can be reported using the "Report a Hazard" form located at www.YaskawaSafety.com.

Leave the "Name" field blank to report the hazard anonymously.

Controlling the Hazards

After identifying a hazard, hazard control measures must be implemented to effectively control the hazard.

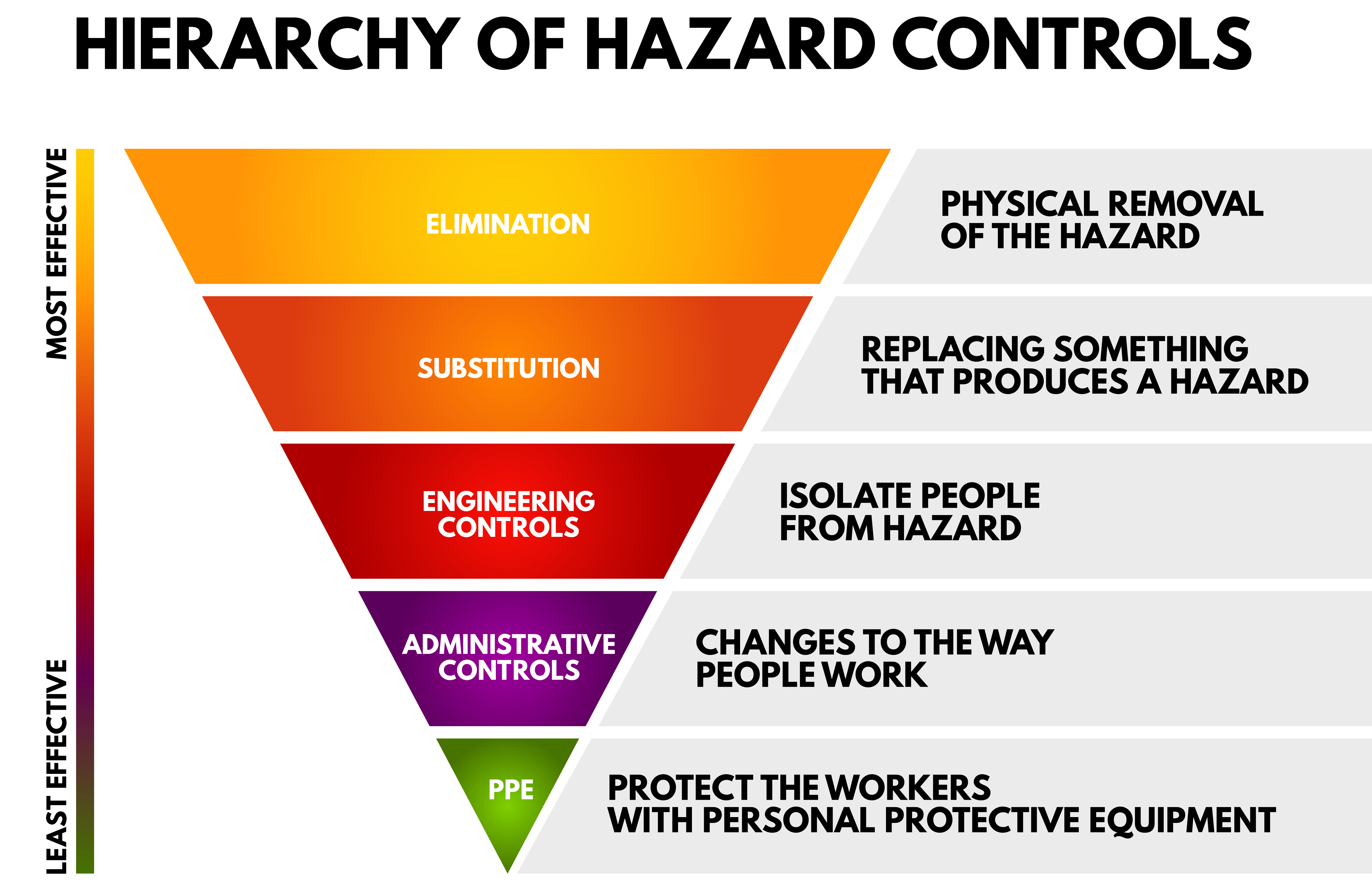

Supervisors should recognize that not all hazard controls are equal. Some controls are more effective than others at reducing risks.

The Hierarchy of controls should be used to determine the order of precedence and effectiveness of hazard controls.

It is often necessary to layer multiple controls. For example, an engineering control is put in place that guards a saw blade. Administrative controls are put in place to restrict the authorized people to properly trained and qualified associates. The qualified associates then must wear PPE in case any of the controls fail.

Results of Breaches of Policy

Breaching this policy may result in an injury. Breaches of this policy may result in disciplinary action being initiated in accordance with Yaskawa America's discipline policy.

Training

All associates shall be provided with training related to this policy.

Revision History

| Rev # |

Description |

Release Date |

Approved by |

| 0 |

Initial Release |

7/14/2016 |

Thurwanger |

| 1 |

Added method for anonomous reporting |

8/5/2022 |

Thurwanger |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Program Review

| Review Date |

Reviewed by |

Changes Required (Yes/No) |

Revision # if updated |

| 2/15/2017 |

Thurwanger |

No |

|

| 1/10/2018 |

Thurwanger |

No |

|

| 1/17/2019 |

Thurwanger |

No |

|

| 1/9/2020 |

Thurwanger |

No |

|

| 1/19/2021 |

Thurwanger |

No |

|

| 1/13/2022 |

Thurwanger |

Yes |

1 |

| 1/26/2023 |

Thurwanger |

No |

|

| 1/11/2024 |

Thurwanger |

No |

|

| 1/16/2025 |

Thurwanger |

No |

|

| 2/11/2026 |

Thurwanger |

No |

|

Safety Triad

Safety Triad

Leave the "Name" field blank to report the hazard anonymously.

Leave the "Name" field blank to report the hazard anonymously.