Job Hazard Analysis

Job Hazard Analysis

HazardAnalysisID: 27

Facility: Waukegan

Assessed By: Thurwanger / Brannaman

Original Assessment Date: 2025-03-12

Work Area: Field Service - Medium Voltage Commissioning

Station: Customer Site

Process: 1. Site Integration & Safety Overwatch Upon arrival, the Yaskawa Field Service Associate (FSA) will conduct a safety briefing with the designated Customer Representative. Competency: The Representative must be fully briefed on the specific hazards of Medium Voltage (MV) commissioning. The "Shadow" Protocol: The Representative must maintain constant visual contact with the FSA. If the Representative is distracted or must leave the area for any reason, a Safety Stop is mandatory. Work remains suspended until the "Shadow" protocol is restored. Emergency Response: The Representative’s primary responsibility is to serve as the emergency communication link to site medical or fire services. 2. Environmental & Work Area Assessment Before initiating technical work, the FSA shall perform a dynamic risk assessment of the immediate environment, identifying hazards such as: Inadequate lighting or egress paths. Environmental contaminants (moisture, conductive dust). Presence of unauthorized personnel within the Limited Approach Boundary. 3. Energy Isolation & Zero-Voltage Verification Though the unit is pre-installed, the FSA assumes a "Trust but Verify" stance regarding energy control: Group Lockout: The FSA must apply a personal lockout device to the customer’s group clasp. PPE Requirements: High-voltage PPE must be donned based on the site-specific Arc Flash label. In the absence of a label, PPE selection must default to the applicable NFPA 70E Tables. Live-Dead-Live Test: The FSA will verify the absence of voltage on all incoming and outgoing points to ensure the drive is in a "Electrically Safe Work Condition." 4. Technical Inspection & Verification With the drive isolated, the FSA performs a comprehensive audit of the third-party contractor’s work: Inspection of all line-side and load-side terminations. Verification of control wiring, grounding integrity, and torque specifications. 5. Re-Energization & Commissioning Once wiring integrity is confirmed, the LOTO devices are removed in coordination with the customer. Initial Power-Up: Power is applied to the MV drive. Parameterization: Customer-specific operational parameters and safety limits are programmed into the drive logic. Validation: The FSA conducts functional testing to ensure the drive operates within the customer’s specific performance envelopes. Conclusion: Commissioning is deemed complete only after the drive demonstrates stable operation and the customer formally accepts the performance verification.

Last Updated: 2026-02-09 15:03:26

Signs: Electric shock and arc flash labels on the drive. Other signs are customer dependant

Barriers: Interlock on drive prevents the doors from being opened when medium voltage is present.

Other Controls: Customer site dependant

Temperature: °F

Noise: 70 dB

Dust: 0

Vapors/Mists: 0

Poor Lighting: 0

Work Alone: 0

-

NFPA 70E Certified:

Successful completion of NFPA 70E certification training renewable every three years -

MV Drive Qualified:

Yaskawa classroom training and On-the-Job training

-

Chemical: None

Secondary Container: No

SDS on File: No

SDS Link: View SDS

-

Tool Description: Voltage Rated Digital Multi-Meter

Tool Inspection: Calibrated -

Tool Description: Hand tools to ensure wiring hardware is secure

Tool Inspection: Wrenches and screw drivers

Personal Protective Equipment (PPE)

| Eye Protection | Head Protection | Hearing Protection |

|---|---|---|

|

✔ Safety Glasses w/ Side Shields Comments: Additional eye protection may be required based on NFPA label or tables |

Comments: Head protection may be required based on NFPA label or tables | Comments: Hearing protection may be required based on NFPA label or tables |

| Hand Protection | Foot Protection | Respiratory Protection |

| No hand protection fields defined |

✔ Electrical Hazard |

|

| Electrical Protection | ||

| Comments: As defined on the NFPA 70E label on the unit or by NFPA 70E Tables in absence of the label | ||

Description: Meet with customer representative and discuss the customer representative's responsibilities. Review the site for hazards. Evaluate the environment. Verify the customer has completed lockout to the drive with a group clasp. Yaskawa engineer adds their lock to the group clasp.

Created: 2026-02-09 | Updated: 2026-02-09

Associated Hazards:

-

Category: Other

Description: Environmental hazards to be assessed on site.

Severity: 5, Likelihood: 2, Score: 10

Control: Customer to present environmental and local hazards with controls. Yaskawa engineer to assess if customer controls are sufficient (If customer control is higher than Yaskawa requirements, associate shall follow customer controls. If Yaskawa controls are greater than customer, the associate shall follow Yaskawa controls).

Walk around work site to identify hazards and determine proper controls.

Created: 2026-02-09 | Updated: 2026-02-09

Description: 1. Assume an energized state until absence of voltage has been verified.

2. Visually verify the digital operator is not operating. Listen to ensure the drive is not operating.

3. Wearing the full PPE required by NFPA study or tables, open the door to the MV drive.

4. Verify operation the digital multiple meter or voltage meter on a known power source

5. Verify absence of voltage to the drive

6. Close and secure MV Drive door.

7. It is now safe to remove PPE

Created: 2026-02-09 | Updated: 2026-02-09

Associated Hazards:

-

Category: Electric Shock or Arc Flash

Description: Electric shock or arc flash

Severity: 10, Likelihood: 4, Score: 40

Control: Door interlocks prevent doors to be opened if medium voltage is present.

Follow PPE requirements on NFPA label, or NFPA 70E tables if incident energy study has not yet been performed.

Created: 2026-02-09 | Updated: 2026-02-09

Description: Inspect all customer supplied wiring to ensure correct termination locations, torque, and clearance. Verify ground bus continuity. Check CT/PT for polarity.

Created: 2026-02-09 | Updated: 2026-02-09

Associated Hazards:

-

Category: Struck-by, Struck-against

Description: Working in tight area increases risk of striking a body part against a fixed object

Severity: 2, Likelihood: 3, Score: 6

Control: Inspect the work area and plan movements

Created: 2026-02-09 | Updated: 2026-02-09

Description: 1. Ensure no tools are left inside the unit

2. Close and latch all doors securely

3. Coordinate with the customer to remove locks and apply power

Created: 2026-02-09 | Updated: 2026-02-09

Associated Hazards:

-

Category: Electric Shock or Arc Flash

Description: Arc Flash during re-energization

Severity: 10, Likelihood: 3, Score: 30

Control: Power turned on at upstream device following left hand rule.

Created: 2026-02-09 | Updated: 2026-02-09

Description: Enter parameters via keypad; verify motor rotation at low speed

Created: 2026-02-09 | Updated: 2026-02-09

Associated Hazards:

-

Category: Other

Description: Internal component failure, Unexpected motor rotation

Severity: 4, Likelihood: 2, Score: 8

Control: Slow start-up

Created: 2026-02-09 | Updated: 2026-02-09

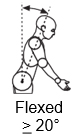

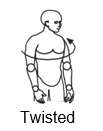

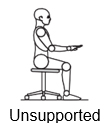

Ergonomic Assessment

Job Hazard Score: 3.20

Hazard Category: Low

Time on Task: 4-19 hours

| Body Part | Posture | Force | Duration | Frequency |

|---|---|---|---|---|

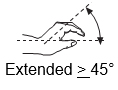

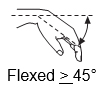

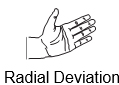

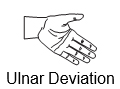

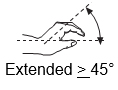

| Left Wrist |

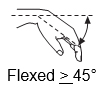

✔ Yes - Extended |

✖ No - Pinch Grip or Finger Press ≥ 2 lbs or Power Grip ≥ 10 lb | ✖ No - ≥ 10 sec | ✖ No - ≥ 30/min |

✔ Yes - Flexed |

||||

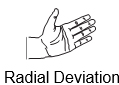

✔ Yes - Radial Deviation |

||||

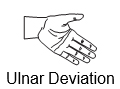

✔ Yes - Ulnar Deviation |

||||

| Right Wrist |

✔ Yes - Extended |

✖ No - Pinch Grip or Finger Press ≥ 2 lbs or Power Grip ≥ 10 lb | ✖ No - ≥ 10 sec | ✖ No - ≥ 30/min |

✔ Yes - Flexed |

||||

✔ Yes - Radial Deviation |

||||

✔ Yes - Ulnar Deviation |

||||

| Left Elbow |

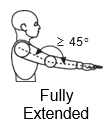

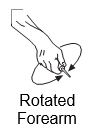

✔ Yes - Extended |

✖ No - ≥ 10 lb | ✖ No - ≥ 10 sec | ✖ No - ≥ 2/min |

✔ Yes - Rotated |

||||

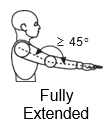

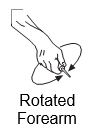

| Right Elbow |

✔ Yes - Extended |

✖ No - ≥ 10 lb | ✖ No - ≥ 10 sec | ✖ No - ≥ 2/min |

✔ Yes - Rotated |

||||

| Left Shoulder |

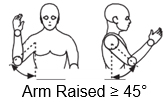

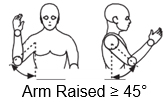

✖ No - Arm Raised |

✖ No - ≥ 10 lb | ✖ No - ≥ 10 sec | ✖ No - ≥ 2/min |

✖ No - Arm Behind |

||||

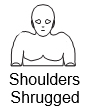

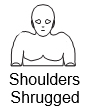

✖ No - Shrugged |

||||

| Right Shoulder |

✖ No - Arm Raised |

✖ No - ≥ 10 lb | ✖ No - ≥ 10 sec | ✖ No - ≥ 2/min |

✖ No - Arm Behind |

||||

✖ No - Shrugged |

||||

| Neck | ||||

| Postures | Force | Duration | Frequency | |

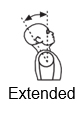

✖ No - Extended |

✖ No - ≥ 2 lb | ✖ No - ≥ 10 sec | ✖ No - ≥ 2/min | |

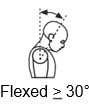

✖ No - Flexed |

||||

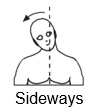

✖ No - Sideways |

||||

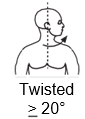

✖ No - Twisted |

||||

| Back | ||||

| Postures | Force | Duration | Frequency | |

✖ No - Extended |

✖ No - ≥ 25 lb | ✖ No - ≥ 10 sec | ✖ No - ≥ 2/min | |

✖ No - Flexed |

||||

✖ No - Sideways |

||||

✖ No - Twisted |

||||

✖ No - Unsupported |

||||

| Legs | ||||

| Postures | Force | Duration | Frequency | |

✖ No - Kneeling |

✖ No - ≥ 10 lb | ✖ No - ≥ 30% of the day | ✖ No - ≥ 2/min | |

✖ No - Squatting |

||||

✖ No - Unsupported |

||||

Ergonomic Stressors

| Stressors | |||

|---|---|---|---|

| Vibration | Low Temperature | Compression | Impact |

| ✖ No - Exposure to vibration | ✖ No - Exposure to cold temperatures | ✖ No - Compression from tool or surface | ✖ No - Exposure to sudden impacts |